- 产品描述

-

Introduction

This machine could laminate 3 papers at one time, 3 channels are fully servo controlled, performing high accuracy. The machine has a wide range of the application, it could adjust automatically when setting up the sheet size.

Features:

★ Cardboard+Flute+Flute

★ Cardboard+Flute

★ Flute+Flute

Technical Parameter

Model TB-3 in 1-1450W TB-3 in 1-1650W Max sheet size 1450×1450mm 1650×1450mm Max sheet size 380*350mm 380*350mm Top paper thickness 120-500g 120-500g Precision for front and back ±1mm ±1mm Speed 120m/min 120m/min Overall 15800*2350*2500mm 16000*2550*2500mm Machine power 40KW 42KW Glue Application White Glue、Starch Glue Bottom paper A、B、C、E、F Corrugated paper

Four Layers Corrugated paper: AB/BB/BC/EE

The cardboard paper above 300GSMDetail parts

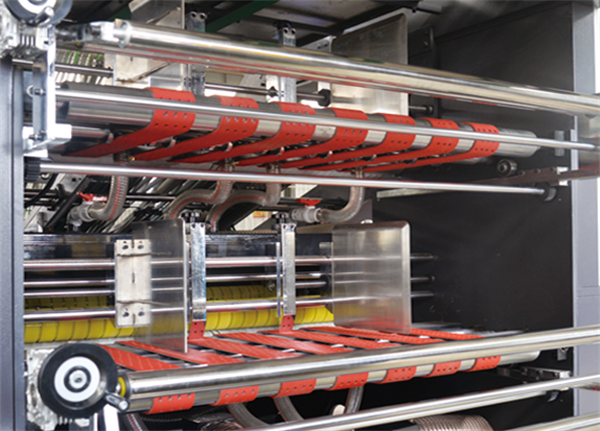

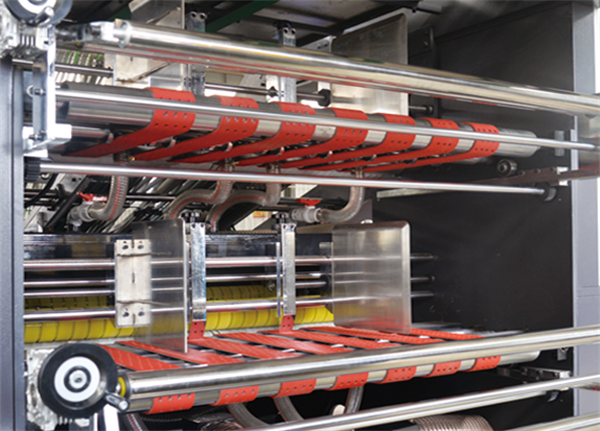

Top sheet feeding system

Adopt high speed four suction and four feeding Feida head, face paper for the double mode of repeated type and broken sheet type, so that the face paper at high speed to achieve smooth and stable operation.

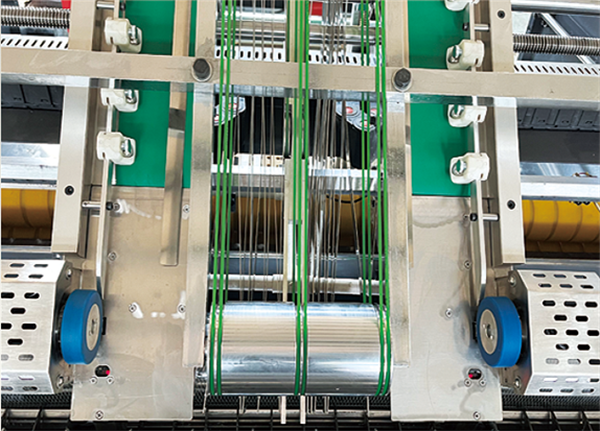

Bottom paper feeding

Double bottom feeding units, double servo motor motion control system, equipped with high pressure suction fan, suction size frequency conversion adjustment, servo motor independent control of suction time, to ensure that different watts of paper running smoothly out of paper.

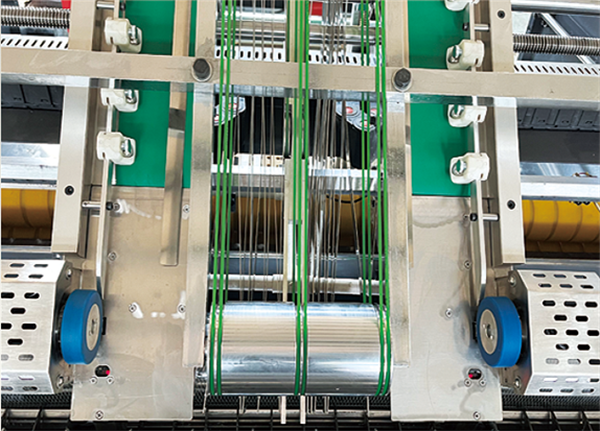

Positioning System

Using groups of photoelectric sensing bottom paper forward relative position, Firstly the 2 bottom corrugation paper will get laminted, then the servo system controls the paper on both sides of the servo motor, independent compensation action, the top paper and bottom paper precision laminated.

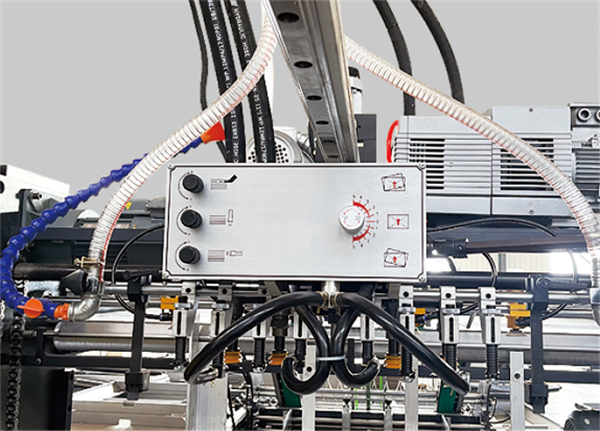

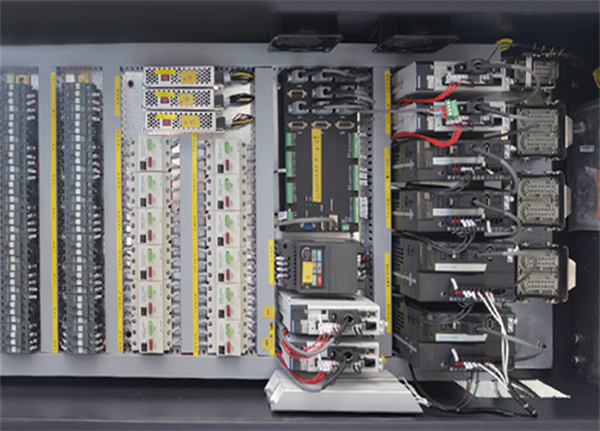

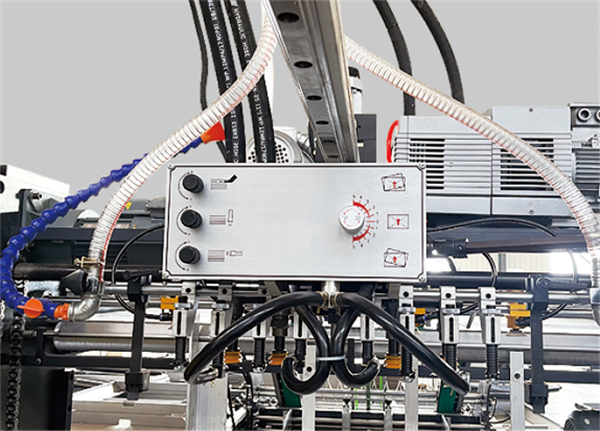

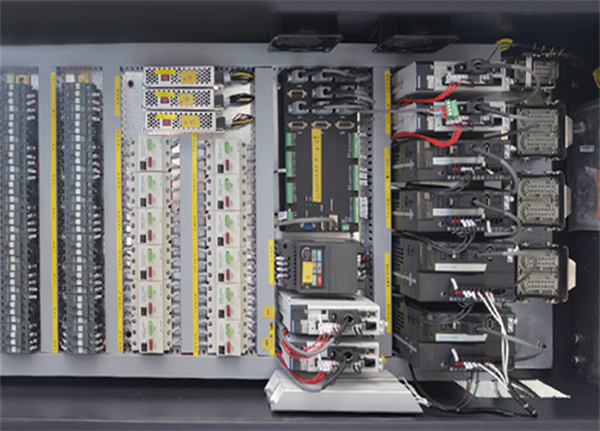

Electrical system

Designed in the accordance with European CE standard, ensuring machine stability, high efficiency and automatic detection for errors.

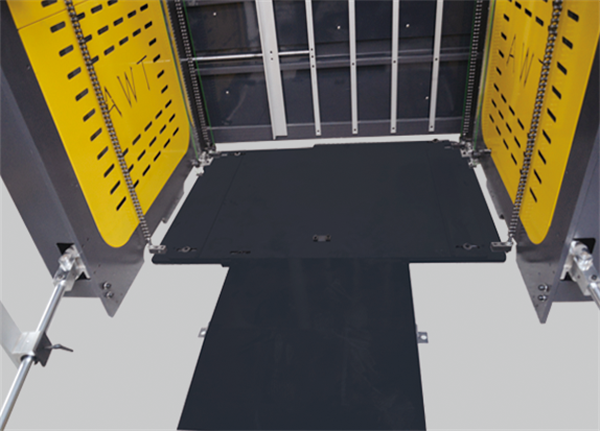

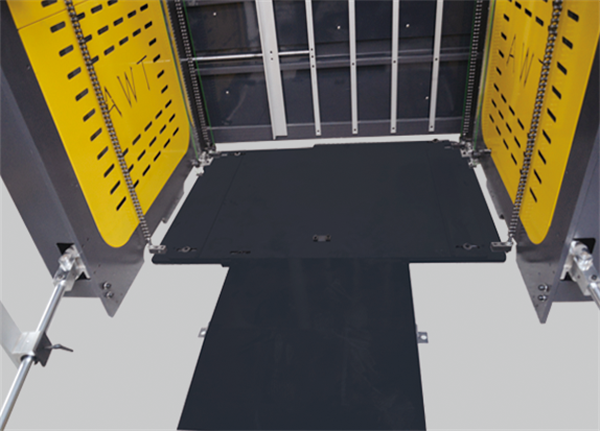

Pre-stack section

The sheets pile could be pushed into the feeding unit, directly by the forklift, time and labor saving.

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

Servo type three in one laminating machine

Share to

- 产品描述

-

Introduction

This machine could laminate 3 papers at one time, 3 channels are fully servo controlled, performing high accuracy. The machine has a wide range of the application, it could adjust automatically when setting up the sheet size.

Features:

★ Cardboard+Flute+Flute

★ Cardboard+Flute

★ Flute+Flute

Technical Parameter

Model TB-3 in 1-1450W TB-3 in 1-1650W Max sheet size 1450×1450mm 1650×1450mm Max sheet size 380*350mm 380*350mm Top paper thickness 120-500g 120-500g Precision for front and back ±1mm ±1mm Speed 120m/min 120m/min Overall 15800*2350*2500mm 16000*2550*2500mm Machine power 40KW 42KW Glue Application White Glue、Starch Glue Bottom paper A、B、C、E、F Corrugated paper

Four Layers Corrugated paper: AB/BB/BC/EE

The cardboard paper above 300GSMDetail parts

Top sheet feeding system

Adopt high speed four suction and four feeding Feida head, face paper for the double mode of repeated type and broken sheet type, so that the face paper at high speed to achieve smooth and stable operation.

Bottom paper feeding

Double bottom feeding units, double servo motor motion control system, equipped with high pressure suction fan, suction size frequency conversion adjustment, servo motor independent control of suction time, to ensure that different watts of paper running smoothly out of paper.

Positioning System

Using groups of photoelectric sensing bottom paper forward relative position, Firstly the 2 bottom corrugation paper will get laminted, then the servo system controls the paper on both sides of the servo motor, independent compensation action, the top paper and bottom paper precision laminated.

Electrical system

Designed in the accordance with European CE standard, ensuring machine stability, high efficiency and automatic detection for errors.

Pre-stack section

The sheets pile could be pushed into the feeding unit, directly by the forklift, time and labor saving.

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

Get Quote Now

Feel free to leave us a message for any inquiry, we will respond within 24 hours.