- 产品描述

-

SUPPLIER TONGBAO CARTON MACHINERY PRODUCTION STANDARDS EU CE certicification standards MODEL TB-STLINE DESCRIPTION TB-STINE Full Automatic Vacuum Transfer Servo feeder Printing Die cutting (Servo motor independent drive) Slotting(Fully computerized) & Folder Gluer & Strapping INLINE SERVO LEAD EDGE FEEDER UNIT

● 4 “Germany Rexroth Servo Drive Pressure-FRESS Lead edge feeder system

● The height of the box can be extended indefinitely, The servo pressure free system has zero damage and zero pressure on the cardboard

● Dust removal device

● Linear guide rail traverses the baffle to enhance adjustment stability and improve paper feeding accuracy

● Electric adjustment left and right baffle

● Electric move the paper tray

● Siemens (Germany) automatic control system(PLC/ /touch screen)

● Inverter DELTA(Taiwan)

● Input box parameter on Main Touch Screen, One-Click change order can be realized

● Industrial control imaging TV monitoring(23.5-inch color display on counter unit+machine-back side imaging display monitor on die cutting unit + lead edge feeder unit + counter unit)1 Unit

PRINTING UNIT/COLOR

● Vacuum transfer

● Printing roller with plate hanging groove, with cushion

● Equipped with automatic ink washing device

● Air distribution gun cleaning printing roller device

● Safety braking device with personnel entering the machine

● Servo controller(Touch Screen) Adjustment machine phase

● Frequency (Touch Screen) Adjustment bellows lift

● Frequency conversion control adsorption air volume

● The air gate automatic adjustment device automatically adjusts the suction area according to the size of the cardboard.

SLOTTING UNIT

● Computerized Synchronous moving slotting & creasing & Pre-creasing, Auto adjust by Touch Screen with memory for setting carton size

● 8 Axis heavy Design,(Pre-creaser)- (Pre-creaser)- (Creaser)- (slotter)

● Pre-creaser shaft core diameter 120mm (solid shaft)

● Creaser shaft core diameter 120mm (solid shaft)

● creaser shaft core diameter 120mm (solid shaft)

● Slotter shaft core diameter 110mm (Seamless steel pipe)

● Slotting left and right traverse speed: 100mm/12seconds

● Servo Controller (Touch Screen) Adjust Machine phase

● Frequency (Touch Screen) Adjust roller gap1 Unit

SERVO DIE CUTTING UNIT

● Servo Drive rotary die cutting system

● Differential compensation device

● Servo motor (Touch screen) to adjust the rotary die cutting phase

● Frequency(Touch screen) adjust roller gap

● Maxdure (Taiwan)die-cutting anvil cover

● Chip blowing device with air duct

● With strapping conveyor belt1 Unit

SERVO FOLDER GLUER UNIT

● Nine servo motors control the operation of the box-gluing and folding section

● Multi-servo driven high-speed counting palletizing collection system ensures high efficiency

● GUANGDONG KQ automatic glue Dispersion System

● It adopts linear guide synchronous traverse system and high-strength bridge in the middle. Group support, stable and accurate displacement

● Folding belt assists vacuum suction for reliable transport of folded cartons

● Equipped with a high-pressure blower to remove waste from the rubber wings1 Unit

STRAPPING UNIT

● Using a high strength blade with a hardness of 65, greatly improving the ability to cut the tape and the life of the blade1 Unit

INDEPENDENT CONTROL CABINET

● Can be connected to the factory production management system

● Enter box parameters to realize one key order adjustment of the whole machine, store 10,000 orders, and quickly change orders1 Unit

Machine Main Parameter

Model TB-STLINE924 TB-STLINE1224 TB-STLINE1228 TB-STLINE1428 Inside width of machine 2600mm 2600mm 3000mm 3000mm Maximum paper size 920x2400mm 1200x2400 1200x2800 1450x2800 Skip feeding size ∞x2400mm ∞x2400mm ∞x2800mm ∞x2800mm Minimum paper size 300x760mm 350x760 350x760 430x760 Maximum printing size 920x2200mm 1200x2200 1200x2600 1450x2600 Design speed of machine 300pcs/min 250pcs/min 250pcs/min 200pcs/min Economic speed of machine 0-300pcs/min 250pcs/min 250pcs/min 200pcs/min Printing paper type A.B.C.E.A/B.B/C and A/B/C flute (The maximum gap is 13mm) Printing plate thickness(plus cushion) 4.8-7.2mm Diameter of printing roller(including printing plate) 300mm 405mm 405mm 480mm Standard printing thickness 1.5-12mm Printing registration precision ≤±0.5mm Slotting precision ≤±1mm Die-cutting precision ≤±1mm The thickness of wall 60mm PLC/Touch screen SIEMENS (GERMANY) Inverter VEICHI(TAIWAN) Servo motor for Lead edge feeder unit Rexroth(GERMANY) Servo motor for die cutting unit VEICHI(TAIWAN) Servo controller for printing unit phase VEICHI(TAIWAN) Servo motor for folder gluer unit VEICHI(TAIWAN) Electric components Schneider(FRANCE) Main motor SIEMENS (GERMANY) Main bearings NSK(JAPAN) Material of main gear 20CrMnTi Material of slotting knife 9CrSi Anvil cover Maxdure(TAIWAN) PRE Feeder

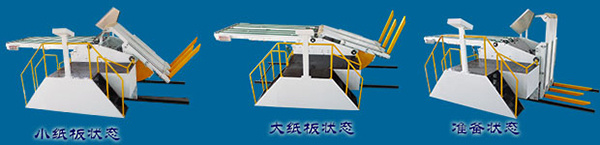

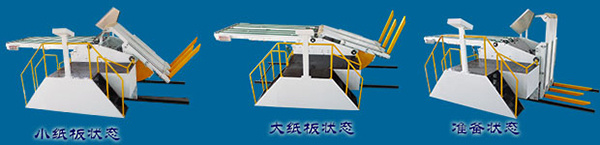

● As long as a hydraulic truck (porter truck) is used, the cardboard square can be placed on the lifting fork, which has strong site applicability.

● In the large cardboard state, the paper can be turned over stack by stack; in the small cardboard state, multiple stacks of cardboard can be raised and lowered, and the paper can be fed in a fish-like shape.

● Cardboard lifting method: hydraulic lifting

● Shift fork flip power: hydraulic drive

● Horizontal conveyor bed lifting power: hydraulic drive

● Conveyor belt power: hydraulic motor (equipped with an independent hydraulic pump station to ensure smooth transportation)

● Side baffles and front baffles, pneumatic alignment correction, side baffle digital adjustment

● Movement of the whole machine: The machine itself can move forward and backward. When the printing machine is separated, the machine automatically moves backward.

● Maintain the height of the cardboard during work, and the lifting fork automatically pushes the cardboard up and down with one click.

The conveyor belt conveys cardboard and can automatically start and stop according to the height of the paper feeding bin of the printing machine.Function Of Feeding(Servo Motor Drive)

SERVO MOTOR DRIVE (ZERO PRESSURE)

● Adopt negative pressure suction flat sun feeding device, suit for any type flute board and any direction feeding, and ensure feeding accuracy.

● Feeding gap accurate adjustment, never damaged strength of the corrugate board

● Adopt pneumatic locking, with protection for overdrive, safe for operation.

● The roller wheel type lead edge feeding vacuum feeding system ensure warped paperboard feeds accurately, skip feeding for large paperboard printing requirement. Automatic return to zero position. Motorized adjustment of feeding roll gap . Continue feeding and skip feeding function.Function Of Printing Department(Vacuum Transfer)

Vacuum transfer

● The vacuum transfer adopted for the whole process feeding is able to feed the cardboard smoothly and precisely which improve the printing precise.

● The gap between vacuum cabinet and printing roller adjusted by PLC and touch screen

● Roller undergoes grinded and plated with rigid chrome, make the balance rectification for running stable

● Anilox and rubber roller structure.

● Anilox roller external diameter is ¢212 mm, steel pipe is plated with grinded surface and laser-carved anilox

● Printing roller diameter: 300mm(including 7.2mm printing plate with liner)

● Printing pressing roller external diameter is ¢188mm,Steel pipe is plated with rigid chrome and grinded surface.

● Ratchet wheel fixed plate axle.

● Loading and unloading printing template, electric controlling CW/CCW rolling by foot switch.

● Printing plate roller traverse PLC control adjustment, movement range +/-5mm

● Automatic pneumatic lifting gear working with feeding system(Anilox roller lowers down to touch printing template during feeding and rises up to leave printing template after stopping feeding.)

● Printing roller circular move adopts PLC, touch screen control and inverter adjustment of 360o.(running and stopping can be adjusted)

● Automatic reposition after washing the printing template during the printing procession.

● Automatic ink washing system.Slotting Unit(Full Computerized)

8 AXIS, 10 SCREW, 5 WHEELS, 3 CREASER

● Creasing wheel with PU Plated for good creasing and avoiding paper crack.

● Creasing rollers diameter:110mm,plated with rigid chrome and grinded surface,treated by balance rectification.

● Slotting holder rollers diameter:176mm,plated with rigid chrome and grinded surface,treated by balance rectification.

● Cast steel slotting guide plates makes slotting precise and never damage the slotting knife.

● 9 Crsi Slotting knives.

● All the knives move and slotting holder move adjusted by PLC control.

● Slotting holder rollers gap adjusted by electric control.

● One-key adjustment, the computer automatically adjusts the slotting knife.Die-Cutting(Servo Motor Drive)

Servo motor drive

● The pad roller adopts a mechanical cam groove movement (40mm) structure. Can move 40mm left and right.

● Die-cutting roller diameter 300mm, cast iron surface grinding and hard chrome plating

● The diameter of the pad roller is 388.9mm, and the surface of the cast iron material is ground and plated with hard chrome

● Electric adjustment of the gap between the die-cutting roller and the rubber pad roller

● The paper feeding roller gap is adjusted by PLC and touch screen

● Feed rollers are finely ground, plated with hard chrome and adjusted for dynamic balance to make the operation more stable

● Die-cut phase electric digital 360° adjustment. (Running and stopping can be adjusted)

● Adopt the speed difference compensation device, no matter how the diameter of the rubber pad changes, the linear speed of the rubber pad will automatically track and compensate without manual adjustment.Gluer Part

● Elastic transmission wheels device, upper and lower belt clamping transmission

● Glue applicator wheel RMP synchronized with folding belts

● Volume of glue application suits for speed of main unit

● Nozzle type glue applicator (Length and position of glue application automatically adjustable)

● GUANGDONG KQ glue Dispersion System.

● Detail of glue dispersion system.● Blower cutting waste clean system.

Folding Part

● High-pressure air blower equipped to get rid of wasted scraps existing at glue flaps

● Folding belts, assisted by vacuum suction, achieve reliable transfer of folding carton

● Pneumatic control of tension of folding belts, released after machine stops, eliminating belts worn-out

● Folding guiding wheels equipped at end of folder, achieve precise folding.

● Both bottom folding belts driven by servo motors independently, greatly reducing big tolerance happened in process of transfer

● Paper jam inspection device

● Extended high strength folding box bridge beam to ensure box folding accuracy and high speed stability.

● Adopt linear guide rail synchronous traverse system, and the middle high -strength type bridge. group support makes stable and accurate displacement

● Elastic guide rail pressing wheels system can control the clearance, effectively solve the paper blockage problem during transferring.

● Rear adsorption belt transmission, independent motor deviation correction device on both sides, effective correctionStacker

● Pressurized roller equipped after folding to force forming of glued & folded cartons, pressure motorized adjustable

● Mechanical organizer pads glued & folded cartons to achieve more precise folding.

● Fully calibrated the calibration device to effectively improve the scissors.

● The behind baffle can be adjusted automatically or manually according to the cardboard specifications

● Automatic emergency stop when cardboard discharge is not smooth

● Pneumatic paper pushing mechanism, high-speed stacking of stacked cartons

● Electric left and right move device (aligned to the center)

● Falling type collection system, effectively protect printing surface from damaging. High production adaptability.● High frequency box correction system, motor fan assisted paper drop, circulation transmission.

● Muti-servo drive high speed counting and stacking collection system, efficient guarantee.● Conveyor belt output, paper pressing wheels assistance, paper transfer our clearance electric adjustment.

● Transversal movement electric adjustment of counting output unit.

Strapping Unit

(1)VOLTAGE :AC380V,50/60Hz

(2)STRAPPING SIZE : min package size : width 80mm *height 60mm Standard

(3)frame size : width 1600mm*height 500mm

(4)Working table height : 850mm

(5)Weight beating capacity :80kg

(6)Strapping strength : 0-45kg

(7)PP wire specs : PP, width 5mm/ 6mm,thickness 0.5-0.8mm

(8)PP Roll width: 170mm-190mm

(9)PP roll inner diameter :200-210mm outer diameter :400-450mm

(10)Adhesion method: hot melt method, bottom bonding, bonding surface ≥90%, and the bonding position deviation ≤ 2mm

(11)Machine weight :280kg

(12)Optional : PP wire width 8mm/9mm/11mm/12mm

(13)Noise : working environment ,noise ≤75dB A

(14)Working environment : humidity 90% , temperature 0-40℃

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

TB-STLINE Full Computer High Speed Printing Slotting Die Cutting & Folding Gluing Inline

Share to

- 产品描述

-

SUPPLIER TONGBAO CARTON MACHINERY PRODUCTION STANDARDS EU CE certicification standards MODEL TB-STLINE DESCRIPTION TB-STINE Full Automatic Vacuum Transfer Servo feeder Printing Die cutting (Servo motor independent drive) Slotting(Fully computerized) & Folder Gluer & Strapping INLINE SERVO LEAD EDGE FEEDER UNIT

● 4 “Germany Rexroth Servo Drive Pressure-FRESS Lead edge feeder system

● The height of the box can be extended indefinitely, The servo pressure free system has zero damage and zero pressure on the cardboard

● Dust removal device

● Linear guide rail traverses the baffle to enhance adjustment stability and improve paper feeding accuracy

● Electric adjustment left and right baffle

● Electric move the paper tray

● Siemens (Germany) automatic control system(PLC/ /touch screen)

● Inverter DELTA(Taiwan)

● Input box parameter on Main Touch Screen, One-Click change order can be realized

● Industrial control imaging TV monitoring(23.5-inch color display on counter unit+machine-back side imaging display monitor on die cutting unit + lead edge feeder unit + counter unit)1 Unit

PRINTING UNIT/COLOR

● Vacuum transfer

● Printing roller with plate hanging groove, with cushion

● Equipped with automatic ink washing device

● Air distribution gun cleaning printing roller device

● Safety braking device with personnel entering the machine

● Servo controller(Touch Screen) Adjustment machine phase

● Frequency (Touch Screen) Adjustment bellows lift

● Frequency conversion control adsorption air volume

● The air gate automatic adjustment device automatically adjusts the suction area according to the size of the cardboard.

SLOTTING UNIT

● Computerized Synchronous moving slotting & creasing & Pre-creasing, Auto adjust by Touch Screen with memory for setting carton size

● 8 Axis heavy Design,(Pre-creaser)- (Pre-creaser)- (Creaser)- (slotter)

● Pre-creaser shaft core diameter 120mm (solid shaft)

● Creaser shaft core diameter 120mm (solid shaft)

● creaser shaft core diameter 120mm (solid shaft)

● Slotter shaft core diameter 110mm (Seamless steel pipe)

● Slotting left and right traverse speed: 100mm/12seconds

● Servo Controller (Touch Screen) Adjust Machine phase

● Frequency (Touch Screen) Adjust roller gap1 Unit

SERVO DIE CUTTING UNIT

● Servo Drive rotary die cutting system

● Differential compensation device

● Servo motor (Touch screen) to adjust the rotary die cutting phase

● Frequency(Touch screen) adjust roller gap

● Maxdure (Taiwan)die-cutting anvil cover

● Chip blowing device with air duct

● With strapping conveyor belt1 Unit

SERVO FOLDER GLUER UNIT

● Nine servo motors control the operation of the box-gluing and folding section

● Multi-servo driven high-speed counting palletizing collection system ensures high efficiency

● GUANGDONG KQ automatic glue Dispersion System

● It adopts linear guide synchronous traverse system and high-strength bridge in the middle. Group support, stable and accurate displacement

● Folding belt assists vacuum suction for reliable transport of folded cartons

● Equipped with a high-pressure blower to remove waste from the rubber wings1 Unit

STRAPPING UNIT

● Using a high strength blade with a hardness of 65, greatly improving the ability to cut the tape and the life of the blade1 Unit

INDEPENDENT CONTROL CABINET

● Can be connected to the factory production management system

● Enter box parameters to realize one key order adjustment of the whole machine, store 10,000 orders, and quickly change orders1 Unit

Machine Main Parameter

Model TB-STLINE924 TB-STLINE1224 TB-STLINE1228 TB-STLINE1428 Inside width of machine 2600mm 2600mm 3000mm 3000mm Maximum paper size 920x2400mm 1200x2400 1200x2800 1450x2800 Skip feeding size ∞x2400mm ∞x2400mm ∞x2800mm ∞x2800mm Minimum paper size 300x760mm 350x760 350x760 430x760 Maximum printing size 920x2200mm 1200x2200 1200x2600 1450x2600 Design speed of machine 300pcs/min 250pcs/min 250pcs/min 200pcs/min Economic speed of machine 0-300pcs/min 250pcs/min 250pcs/min 200pcs/min Printing paper type A.B.C.E.A/B.B/C and A/B/C flute (The maximum gap is 13mm) Printing plate thickness(plus cushion) 4.8-7.2mm Diameter of printing roller(including printing plate) 300mm 405mm 405mm 480mm Standard printing thickness 1.5-12mm Printing registration precision ≤±0.5mm Slotting precision ≤±1mm Die-cutting precision ≤±1mm The thickness of wall 60mm PLC/Touch screen SIEMENS (GERMANY) Inverter VEICHI(TAIWAN) Servo motor for Lead edge feeder unit Rexroth(GERMANY) Servo motor for die cutting unit VEICHI(TAIWAN) Servo controller for printing unit phase VEICHI(TAIWAN) Servo motor for folder gluer unit VEICHI(TAIWAN) Electric components Schneider(FRANCE) Main motor SIEMENS (GERMANY) Main bearings NSK(JAPAN) Material of main gear 20CrMnTi Material of slotting knife 9CrSi Anvil cover Maxdure(TAIWAN) PRE Feeder

● As long as a hydraulic truck (porter truck) is used, the cardboard square can be placed on the lifting fork, which has strong site applicability.

● In the large cardboard state, the paper can be turned over stack by stack; in the small cardboard state, multiple stacks of cardboard can be raised and lowered, and the paper can be fed in a fish-like shape.

● Cardboard lifting method: hydraulic lifting

● Shift fork flip power: hydraulic drive

● Horizontal conveyor bed lifting power: hydraulic drive

● Conveyor belt power: hydraulic motor (equipped with an independent hydraulic pump station to ensure smooth transportation)

● Side baffles and front baffles, pneumatic alignment correction, side baffle digital adjustment

● Movement of the whole machine: The machine itself can move forward and backward. When the printing machine is separated, the machine automatically moves backward.

● Maintain the height of the cardboard during work, and the lifting fork automatically pushes the cardboard up and down with one click.

The conveyor belt conveys cardboard and can automatically start and stop according to the height of the paper feeding bin of the printing machine.Function Of Feeding(Servo Motor Drive)

SERVO MOTOR DRIVE (ZERO PRESSURE)

● Adopt negative pressure suction flat sun feeding device, suit for any type flute board and any direction feeding, and ensure feeding accuracy.

● Feeding gap accurate adjustment, never damaged strength of the corrugate board

● Adopt pneumatic locking, with protection for overdrive, safe for operation.

● The roller wheel type lead edge feeding vacuum feeding system ensure warped paperboard feeds accurately, skip feeding for large paperboard printing requirement. Automatic return to zero position. Motorized adjustment of feeding roll gap . Continue feeding and skip feeding function.Function Of Printing Department(Vacuum Transfer)

Vacuum transfer

● The vacuum transfer adopted for the whole process feeding is able to feed the cardboard smoothly and precisely which improve the printing precise.

● The gap between vacuum cabinet and printing roller adjusted by PLC and touch screen

● Roller undergoes grinded and plated with rigid chrome, make the balance rectification for running stable

● Anilox and rubber roller structure.

● Anilox roller external diameter is ¢212 mm, steel pipe is plated with grinded surface and laser-carved anilox

● Printing roller diameter: 300mm(including 7.2mm printing plate with liner)

● Printing pressing roller external diameter is ¢188mm,Steel pipe is plated with rigid chrome and grinded surface.

● Ratchet wheel fixed plate axle.

● Loading and unloading printing template, electric controlling CW/CCW rolling by foot switch.

● Printing plate roller traverse PLC control adjustment, movement range +/-5mm

● Automatic pneumatic lifting gear working with feeding system(Anilox roller lowers down to touch printing template during feeding and rises up to leave printing template after stopping feeding.)

● Printing roller circular move adopts PLC, touch screen control and inverter adjustment of 360o.(running and stopping can be adjusted)

● Automatic reposition after washing the printing template during the printing procession.

● Automatic ink washing system.Slotting Unit(Full Computerized)

8 AXIS, 10 SCREW, 5 WHEELS, 3 CREASER

● Creasing wheel with PU Plated for good creasing and avoiding paper crack.

● Creasing rollers diameter:110mm,plated with rigid chrome and grinded surface,treated by balance rectification.

● Slotting holder rollers diameter:176mm,plated with rigid chrome and grinded surface,treated by balance rectification.

● Cast steel slotting guide plates makes slotting precise and never damage the slotting knife.

● 9 Crsi Slotting knives.

● All the knives move and slotting holder move adjusted by PLC control.

● Slotting holder rollers gap adjusted by electric control.

● One-key adjustment, the computer automatically adjusts the slotting knife.Die-Cutting(Servo Motor Drive)

Servo motor drive

● The pad roller adopts a mechanical cam groove movement (40mm) structure. Can move 40mm left and right.

● Die-cutting roller diameter 300mm, cast iron surface grinding and hard chrome plating

● The diameter of the pad roller is 388.9mm, and the surface of the cast iron material is ground and plated with hard chrome

● Electric adjustment of the gap between the die-cutting roller and the rubber pad roller

● The paper feeding roller gap is adjusted by PLC and touch screen

● Feed rollers are finely ground, plated with hard chrome and adjusted for dynamic balance to make the operation more stable

● Die-cut phase electric digital 360° adjustment. (Running and stopping can be adjusted)

● Adopt the speed difference compensation device, no matter how the diameter of the rubber pad changes, the linear speed of the rubber pad will automatically track and compensate without manual adjustment.Gluer Part

● Elastic transmission wheels device, upper and lower belt clamping transmission

● Glue applicator wheel RMP synchronized with folding belts

● Volume of glue application suits for speed of main unit

● Nozzle type glue applicator (Length and position of glue application automatically adjustable)

● GUANGDONG KQ glue Dispersion System.

● Detail of glue dispersion system.● Blower cutting waste clean system.

Folding Part

● High-pressure air blower equipped to get rid of wasted scraps existing at glue flaps

● Folding belts, assisted by vacuum suction, achieve reliable transfer of folding carton

● Pneumatic control of tension of folding belts, released after machine stops, eliminating belts worn-out

● Folding guiding wheels equipped at end of folder, achieve precise folding.

● Both bottom folding belts driven by servo motors independently, greatly reducing big tolerance happened in process of transfer

● Paper jam inspection device

● Extended high strength folding box bridge beam to ensure box folding accuracy and high speed stability.

● Adopt linear guide rail synchronous traverse system, and the middle high -strength type bridge. group support makes stable and accurate displacement

● Elastic guide rail pressing wheels system can control the clearance, effectively solve the paper blockage problem during transferring.

● Rear adsorption belt transmission, independent motor deviation correction device on both sides, effective correctionStacker

● Pressurized roller equipped after folding to force forming of glued & folded cartons, pressure motorized adjustable

● Mechanical organizer pads glued & folded cartons to achieve more precise folding.

● Fully calibrated the calibration device to effectively improve the scissors.

● The behind baffle can be adjusted automatically or manually according to the cardboard specifications

● Automatic emergency stop when cardboard discharge is not smooth

● Pneumatic paper pushing mechanism, high-speed stacking of stacked cartons

● Electric left and right move device (aligned to the center)

● Falling type collection system, effectively protect printing surface from damaging. High production adaptability.● High frequency box correction system, motor fan assisted paper drop, circulation transmission.

● Muti-servo drive high speed counting and stacking collection system, efficient guarantee.● Conveyor belt output, paper pressing wheels assistance, paper transfer our clearance electric adjustment.

● Transversal movement electric adjustment of counting output unit.

Strapping Unit

(1)VOLTAGE :AC380V,50/60Hz

(2)STRAPPING SIZE : min package size : width 80mm *height 60mm Standard

(3)frame size : width 1600mm*height 500mm

(4)Working table height : 850mm

(5)Weight beating capacity :80kg

(6)Strapping strength : 0-45kg

(7)PP wire specs : PP, width 5mm/ 6mm,thickness 0.5-0.8mm

(8)PP Roll width: 170mm-190mm

(9)PP roll inner diameter :200-210mm outer diameter :400-450mm

(10)Adhesion method: hot melt method, bottom bonding, bonding surface ≥90%, and the bonding position deviation ≤ 2mm

(11)Machine weight :280kg

(12)Optional : PP wire width 8mm/9mm/11mm/12mm

(13)Noise : working environment ,noise ≤75dB A

(14)Working environment : humidity 90% , temperature 0-40℃

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

Get Quote Now

Feel free to leave us a message for any inquiry, we will respond within 24 hours.