- 产品描述

-

Functions and features

● Dual servo drives imported from Mitsubishi Japan have accurate precision, reduce mechanical transmission, and effectively reduce machine failure rates.

● Mitsubishi touch screen operation, parameters (nail distance, number of nails, nail type, tailgate) can be quickly Easy to change.

● The entire control system adopts Japanese Mitsubishi PLC control system.

● The last electric baffle is driven by a stepper motor, with accurate dimensions and easy size replacement.

● All contactors in the control box are of Mitsubishi brand.

● Photoelectric and proximity switches adopt the Schneider brand.

● The bottom mold and blade are made of Japanese tungsten steel (wear-resistant).

● The entire set of nail heads is made of special steel and precision processed by computer.

● Single nail/, double nail//, reinforced nail (///////double nail at both ends and single nail in the middle) Completed at one time, it can meet the requirements of different customers for different nail types.

● Changing the size of the carton and adjusting the nail spacing of the carton can be completed in one minute, saving time and making it easy to operate.

● The front-end paper feeding section automatically counts, and the paper feeding table is equipped with a photoelectric sensor, which automatically rises when feeding paper.

● The rear section has an automatic counting function, and the finished products can be stacked and sent to the end of the conveyor according to the set quantity (1-99) for convenient packaging.

Technical parameter

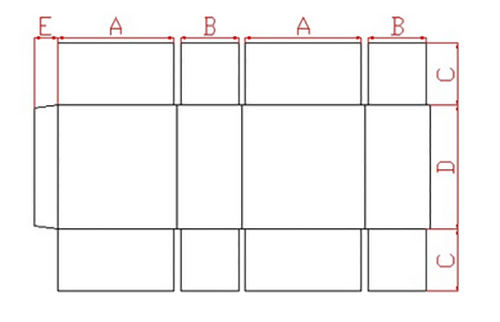

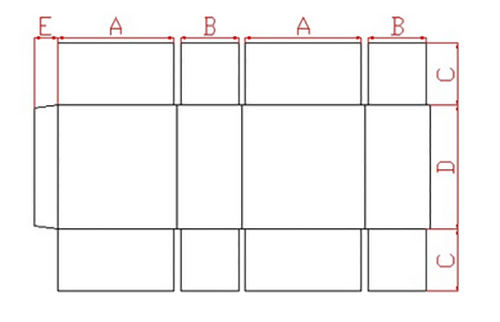

Model and technical data TB-2000D Maximum paper size (A+B)*2(mm) 3600 Minimum paper size (A+B)*2(mm) 740 Maximum carton length A mm 1140 Minimum carton length A mm 250 Maximum carton width B mm 850 Minimum carton width B mm 120 Maximum cardboard height (C+D+C) (mm) 3000 Minimum cardboard height (C+D+C) (mm) 250 Maximum swing cover size C (mm) 560 Minimum flip cover size C (mm) 50 Maximum height D(mm) 2000 Minimum height D(mm) 150 Maximum nail tongue width E (mm) 40 Nail distance (mm) 30-150 digital nails 1-99 Nail speed (nail/min) 500

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

Semi auto stitching machine

Share to

- 产品描述

-

Functions and features

● Dual servo drives imported from Mitsubishi Japan have accurate precision, reduce mechanical transmission, and effectively reduce machine failure rates.

● Mitsubishi touch screen operation, parameters (nail distance, number of nails, nail type, tailgate) can be quickly Easy to change.

● The entire control system adopts Japanese Mitsubishi PLC control system.

● The last electric baffle is driven by a stepper motor, with accurate dimensions and easy size replacement.

● All contactors in the control box are of Mitsubishi brand.

● Photoelectric and proximity switches adopt the Schneider brand.

● The bottom mold and blade are made of Japanese tungsten steel (wear-resistant).

● The entire set of nail heads is made of special steel and precision processed by computer.

● Single nail/, double nail//, reinforced nail (///////double nail at both ends and single nail in the middle) Completed at one time, it can meet the requirements of different customers for different nail types.

● Changing the size of the carton and adjusting the nail spacing of the carton can be completed in one minute, saving time and making it easy to operate.

● The front-end paper feeding section automatically counts, and the paper feeding table is equipped with a photoelectric sensor, which automatically rises when feeding paper.

● The rear section has an automatic counting function, and the finished products can be stacked and sent to the end of the conveyor according to the set quantity (1-99) for convenient packaging.

Technical parameter

Model and technical data TB-2000D Maximum paper size (A+B)*2(mm) 3600 Minimum paper size (A+B)*2(mm) 740 Maximum carton length A mm 1140 Minimum carton length A mm 250 Maximum carton width B mm 850 Minimum carton width B mm 120 Maximum cardboard height (C+D+C) (mm) 3000 Minimum cardboard height (C+D+C) (mm) 250 Maximum swing cover size C (mm) 560 Minimum flip cover size C (mm) 50 Maximum height D(mm) 2000 Minimum height D(mm) 150 Maximum nail tongue width E (mm) 40 Nail distance (mm) 30-150 digital nails 1-99 Nail speed (nail/min) 500

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

Get Quote Now

Feel free to leave us a message for any inquiry, we will respond within 24 hours.