- 产品描述

-

Function

The fully automatic gluing stitching all-in-one machine is composed of a paper feeding part, a folding part, a nail box part, a correction part and a counting output part. It adopts PLC computer control, one-key adjustment of input data, order storage, and easy operation. The sticky nails of the main machine are separated up and down, one-button conversion, left and right electric traverse. Nailing and sticking independent power operation, convenient, quick and efficient adjustment.

Feeding

The wallboard is welded with steel plate. The transmission shaft is welded with seamless steel pipe, the pipe wall thickness is 20mm, the shaft surface is plated with hard chromium, and the bearing is made in WAGANGDIAN, Harbin. High pressure fan is used to feed the paperboard to ensure stable paper feeding. Each wear-resistant air suction belt can control the air volume separately to ensure the smooth feeding of paperboard. Drive synchronous toothed belt for paper feeding and smooth operation.

Folding

The folding part adopts two kinds of pressing: pre pressing wheel and forming wheel, and then re strengthens the paperboard pressing line on the original pressing line. The position is accurate, the paperboard is not broken, the folding is beautiful, and the flat belt is pressed, folded and the synchronous belt is used to transport the finished products smoothly.

Stitching

The servo motor of the nail box is independently controlled, with automatic paper feeding, automatic nailing and automatic counting. The machine head is made of special material, which is wear-resistant and stable with low noise. The head servo motor is directly driven with high speed and accurate nail distance. Large plate nail line reduces wire change time and improves work efficiency.

Correction unit

The bearing eccentricity correction (with differential correction) makes the paperboard folding beautiful, and the size of the correction part can be adjusted horizontally.

Counting output unit

Finished cartons are stacked and output, so that cartons can be output, and packaged smoothly.

Note: This machine is suitable for three-layer and five layer single-chip carton nailing boxes.

Core technology

● Fast carton forming speed

● Accurate air suction and paper feeding

● Secondary indentation makes the crease more accurate without fracture

● The size of the mouth is well controlled to reduce waste products

● Secondary deviation correction and elimination of scissors

● Accurate counting

Electric machinery

● The motor adopts domestic well-known brand transmission(Zhejiang, Shanghai, Guangdong).

High pressure fan is adopted with stable quality.

● Shanghai YANDE transmission Co., Ltd. is adopted for electromagnetic clutch and electromagnetic brake.

● The conveyor belt of the whole machine adopts German brand [SIEGLING].

● Servo motor of nail box, Mitsubishi, Japan

Technical Parameters

Supplier TONGBAO CARTON MACHINERY CO.,LTD Description TB-LC3000 automatic folder gluer stitcher machine Machine Parameter

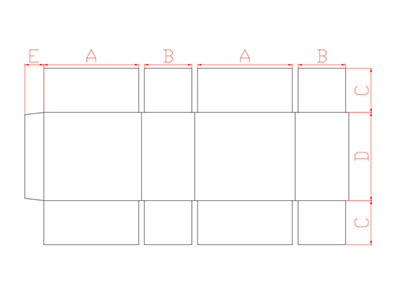

Model/Parameters TB-LC3000 Max paper size (A+B)X2(mm) 2800mm Min paper size (A+B)X2(mm) 780mm The biggest paper height(C+D+C)(mm) 1400mm The smallest paper height(C+D+C)(mm) 400mm Max width of tongue(mm) 40 Nail distance(mm) 30-80mm Nail number 1-99 Nailing speed(Nails/Min) 800 Total power 23kw Parameter configuration

Name model origin of electric appliance PLC Omron Japan Touch screen Beijing Kunlun Tongtai 7-inch Beijing Contactor Schneider 0901 Germany Intermediate relay Omron Japan Emergency stop Siemens/Chint Germany/China Button Siemens Germany Key switch Siemens Germany Travel switch Chint China Photoelectric switch Beifuning China Wiring terminal Beifuning 1530 China Cooling fan China Bell China Thermal overload relay Schneider Germany Air switch 3P Schneider Germany Air switch 1p Schneider Germany Large load rectangular plug-in China Aviation plug-in China Transformer 300VA China Frequency converter Delta M series Taiwan, China

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

TB-LC Automatic stitcher and gluer machine

Share to

- 产品描述

-

Function

The fully automatic gluing stitching all-in-one machine is composed of a paper feeding part, a folding part, a nail box part, a correction part and a counting output part. It adopts PLC computer control, one-key adjustment of input data, order storage, and easy operation. The sticky nails of the main machine are separated up and down, one-button conversion, left and right electric traverse. Nailing and sticking independent power operation, convenient, quick and efficient adjustment.

Feeding

The wallboard is welded with steel plate. The transmission shaft is welded with seamless steel pipe, the pipe wall thickness is 20mm, the shaft surface is plated with hard chromium, and the bearing is made in WAGANGDIAN, Harbin. High pressure fan is used to feed the paperboard to ensure stable paper feeding. Each wear-resistant air suction belt can control the air volume separately to ensure the smooth feeding of paperboard. Drive synchronous toothed belt for paper feeding and smooth operation.

Folding

The folding part adopts two kinds of pressing: pre pressing wheel and forming wheel, and then re strengthens the paperboard pressing line on the original pressing line. The position is accurate, the paperboard is not broken, the folding is beautiful, and the flat belt is pressed, folded and the synchronous belt is used to transport the finished products smoothly.

Stitching

The servo motor of the nail box is independently controlled, with automatic paper feeding, automatic nailing and automatic counting. The machine head is made of special material, which is wear-resistant and stable with low noise. The head servo motor is directly driven with high speed and accurate nail distance. Large plate nail line reduces wire change time and improves work efficiency.

Correction unit

The bearing eccentricity correction (with differential correction) makes the paperboard folding beautiful, and the size of the correction part can be adjusted horizontally.

Counting output unit

Finished cartons are stacked and output, so that cartons can be output, and packaged smoothly.

Note: This machine is suitable for three-layer and five layer single-chip carton nailing boxes.

Core technology

● Fast carton forming speed

● Accurate air suction and paper feeding

● Secondary indentation makes the crease more accurate without fracture

● The size of the mouth is well controlled to reduce waste products

● Secondary deviation correction and elimination of scissors

● Accurate counting

Electric machinery

● The motor adopts domestic well-known brand transmission(Zhejiang, Shanghai, Guangdong).

High pressure fan is adopted with stable quality.

● Shanghai YANDE transmission Co., Ltd. is adopted for electromagnetic clutch and electromagnetic brake.

● The conveyor belt of the whole machine adopts German brand [SIEGLING].

● Servo motor of nail box, Mitsubishi, Japan

Technical Parameters

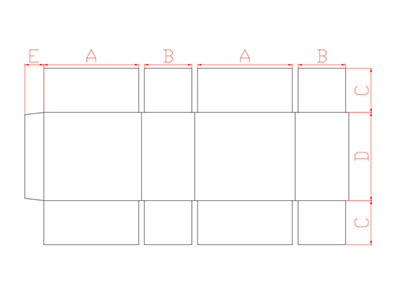

Supplier TONGBAO CARTON MACHINERY CO.,LTD Description TB-LC3000 automatic folder gluer stitcher machine Machine Parameter

Model/Parameters TB-LC3000 Max paper size (A+B)X2(mm) 2800mm Min paper size (A+B)X2(mm) 780mm The biggest paper height(C+D+C)(mm) 1400mm The smallest paper height(C+D+C)(mm) 400mm Max width of tongue(mm) 40 Nail distance(mm) 30-80mm Nail number 1-99 Nailing speed(Nails/Min) 800 Total power 23kw Parameter configuration

Name model origin of electric appliance PLC Omron Japan Touch screen Beijing Kunlun Tongtai 7-inch Beijing Contactor Schneider 0901 Germany Intermediate relay Omron Japan Emergency stop Siemens/Chint Germany/China Button Siemens Germany Key switch Siemens Germany Travel switch Chint China Photoelectric switch Beifuning China Wiring terminal Beifuning 1530 China Cooling fan China Bell China Thermal overload relay Schneider Germany Air switch 3P Schneider Germany Air switch 1p Schneider Germany Large load rectangular plug-in China Aviation plug-in China Transformer 300VA China Frequency converter Delta M series Taiwan, China

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

Get Quote Now

Feel free to leave us a message for any inquiry, we will respond within 24 hours.