- 产品描述

-

Function and characteristics

● The use of the patented lead edge feeding structure can effectively prevent and reduce the damage to the paper printing surface.

● This machine is mainly used for corrugated paper of no less than 8.5mm.

● The main chain (Germany) adopts heavy load and high precision transmission chain, with very small production error, high tensile strength and wear resistance.

● There are two ways of receiving paper, such as towing board and trolley, which greatly improve the working efficiency. It has photoelectric detection device, safe and reliable, and ensure the fast and steady receiving of paper.

● It has overload protection mechanism, to achieve accidental overload, active separation of the die - cutting board frame can effectively prevent the die - cutting board sagging and fall off.

● Pneumatic lock plate mechanism adopts imported cylinder, stable performance, convenient and fast operation.

● The electric control system is controlled by PLC and equipped with various safety protection devices, which can give audible and visual alarm in case of failure and shut down automatically, truly guaranteeing the man-machine safety.

● The timing and quantitative automatic oil supply system can ensure the full lubrication of other moving parts of the machine and have long service life.

SUPPLIER TONGBAO CARTON MACHINERY PRODUCTION STANDARDS EU CE certicification standards MODEL TB-MYQ DESCRIPTION TB-MYQ automatic die cutting creasing machine Lead edge feeder

● The leading edge feed adopts vacuum adsorption feed and is driven by international famous brand servo motor.

● The use of the patented pre edge feed structure can effectively prevent and reduce the damage to the paper printing surface.

● Use high-quality steel to securely install and secure, easy to operate.

● Equipped with reflective photoelectric, it can automatically lift and adjust the position of the photoelectric according to whether the paper is bent to ensure the paper feeding front and paper baffle.1 Unit

Feeding table

● It is equipped with opposite photoelectricity. It can automatically lift and manually adjust the lifting distance.

● It can also adjust the photoelectric position according to whether the paper is bent to ensure that the front edge of the continuous paper is flush with the paper feed bezel

● Automatic alignment and alignment before cardboard die-cutting

● Electrical mechanical double sheet detector

● Sheet hold-down device (guiding the sheets to the front lays)1 Unit

Die-cutting unit

● Maximum working die cutting pressure 350T

● The main wall panel is made of high-quality ductile iron, and the upper platform and movable platform are also made of high-quality ductile iron to ensure its ability to resist compression, deformation and vibration.

● The main machine is driven by a worm gear, with large torque, stable and reliable transmission, low noise and long service life.

● It is also equipped with a forced lubrication oil pump to realize the oil supply volume of each lubrication point. The mold-cutter version is easy to install, can be extracted freely, and the plate time is short.

● Cam indexer and heavy duty pneumatic clutch with overload protection for stable, accurate and safe machine running.1 Unit

Stacker unit

● Automatic counting, dispersion board alarm. Automatic paper drop, automatic warning and paper drop is full.

● According to the product size, adjust the left and right, front and back, and front of the cardboard to achieve the paper feeding level.

● Delivery control panel with icons for easy operation.

● Photoelectric device for safe operation and entrance.

● Auto lubrication device for all gears and chains1 Unit

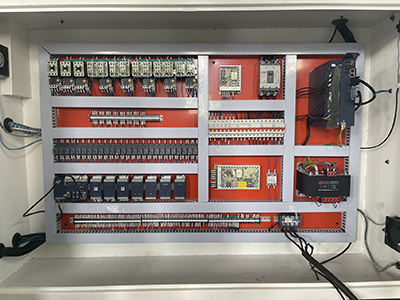

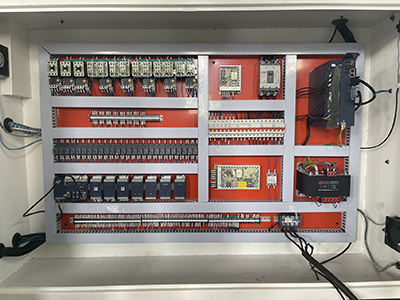

Electrical control section

● Adopts electrical components of world famous brands for better performance and in time and local after-sale-service and maintenance.

● latest PLC technology to ensure safe and trouble free running1 Unit

Machine Main Parameter

Model MYQ-1300 MYQ-1520 MYQ-1650 Maximum paper size 1300x930mm 1520x1120mm 1650x1200mm Minimum paper size 400x450mm 400x450mm 500x550mm Maximum die cutting size 1280x910mm 1500x1100mm 1630x1180mm Design speed of machine 5000pcs/h 5000pcs/h 5000pcs/h Economic speed of machine 0-5000pcs/h Die-cutting paper type E,D.B,C,A and AB flute corrugated paper(1-8.5mm thickness) Die-cutting precision ≤±0.5mm Max. working pressure 350T 380T 400T Total power 25KW 26.5KW 32KW Feeding part

● Use high quality steel to install and fix firmly, easy to operate.

● Can be in the normal continuation of paper work, code installed the next die-cutting paper, there is no need to cause code paper link caused by the waste of time.

● The use of the patented preedge feed structure can effectively prevent and reduce the damage to the paper printing surface.

● The leading edge feed adopts vacuum adsorption feed and is driven by domestic famous brand servo motor.

● Equipped with counter photoelectric, can automatically rise and fall, but also according to whether the paper is bent, adjust the photoelectric position, in order to ensure that the feeding front and the paper baffle flat.Feeding Table

● It is equipped with opposite photoelectricity. It can automatically lift and manually adjust the lifting distance.

● It can also adjust the photoelectric position according to whether the paper is bent or not, so as to ensure that the front edge of the continued paper is flush with the feed baffle.Die-cutting part and Delivery system

● The maximum die-cutting pressure

● of the main machine is 350N/cm².

● The main engine is driven by worm wheel and worm, with large torque, stable and reliable transmission, low noise and long service life.

● The main wall panel is made of high quality ductile iron, and the upper platform and the moving platform are also made of high quality ductile iron, so as to ensure its ability to resist compression, deformation and vibration.

● And equipped with a forced lubricating oil pump, the realization of each lubrication point oil quantity. Die - cutting knife version easy installation, extraction freely, short version time.(the bearings and electrical parts are selected from well-known foreign brands)Stacker part

● Automatic counting, scattered board alarm. Automatic drop of paper receiving, automatic warning and falling of paper receiving full.

● According to the size of the product, adjust the left and right and front and back of the paperboard to achieve the paper receiving level.Electric system

● The electronic control system is controlled by PLC and equipped with various safety protection devices. When the fault occurs, the sound and light alarm will be given and the machine will stop automatically to ensure the safety of man and machine.

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

TB-MYQ Automatic Die cutting Machine

Share to

- 产品描述

-

Function and characteristics

● The use of the patented lead edge feeding structure can effectively prevent and reduce the damage to the paper printing surface.

● This machine is mainly used for corrugated paper of no less than 8.5mm.

● The main chain (Germany) adopts heavy load and high precision transmission chain, with very small production error, high tensile strength and wear resistance.

● There are two ways of receiving paper, such as towing board and trolley, which greatly improve the working efficiency. It has photoelectric detection device, safe and reliable, and ensure the fast and steady receiving of paper.

● It has overload protection mechanism, to achieve accidental overload, active separation of the die - cutting board frame can effectively prevent the die - cutting board sagging and fall off.

● Pneumatic lock plate mechanism adopts imported cylinder, stable performance, convenient and fast operation.

● The electric control system is controlled by PLC and equipped with various safety protection devices, which can give audible and visual alarm in case of failure and shut down automatically, truly guaranteeing the man-machine safety.

● The timing and quantitative automatic oil supply system can ensure the full lubrication of other moving parts of the machine and have long service life.

SUPPLIER TONGBAO CARTON MACHINERY PRODUCTION STANDARDS EU CE certicification standards MODEL TB-MYQ DESCRIPTION TB-MYQ automatic die cutting creasing machine Lead edge feeder

● The leading edge feed adopts vacuum adsorption feed and is driven by international famous brand servo motor.

● The use of the patented pre edge feed structure can effectively prevent and reduce the damage to the paper printing surface.

● Use high-quality steel to securely install and secure, easy to operate.

● Equipped with reflective photoelectric, it can automatically lift and adjust the position of the photoelectric according to whether the paper is bent to ensure the paper feeding front and paper baffle.1 Unit

Feeding table

● It is equipped with opposite photoelectricity. It can automatically lift and manually adjust the lifting distance.

● It can also adjust the photoelectric position according to whether the paper is bent to ensure that the front edge of the continuous paper is flush with the paper feed bezel

● Automatic alignment and alignment before cardboard die-cutting

● Electrical mechanical double sheet detector

● Sheet hold-down device (guiding the sheets to the front lays)1 Unit

Die-cutting unit

● Maximum working die cutting pressure 350T

● The main wall panel is made of high-quality ductile iron, and the upper platform and movable platform are also made of high-quality ductile iron to ensure its ability to resist compression, deformation and vibration.

● The main machine is driven by a worm gear, with large torque, stable and reliable transmission, low noise and long service life.

● It is also equipped with a forced lubrication oil pump to realize the oil supply volume of each lubrication point. The mold-cutter version is easy to install, can be extracted freely, and the plate time is short.

● Cam indexer and heavy duty pneumatic clutch with overload protection for stable, accurate and safe machine running.1 Unit

Stacker unit

● Automatic counting, dispersion board alarm. Automatic paper drop, automatic warning and paper drop is full.

● According to the product size, adjust the left and right, front and back, and front of the cardboard to achieve the paper feeding level.

● Delivery control panel with icons for easy operation.

● Photoelectric device for safe operation and entrance.

● Auto lubrication device for all gears and chains1 Unit

Electrical control section

● Adopts electrical components of world famous brands for better performance and in time and local after-sale-service and maintenance.

● latest PLC technology to ensure safe and trouble free running1 Unit

Machine Main Parameter

Model MYQ-1300 MYQ-1520 MYQ-1650 Maximum paper size 1300x930mm 1520x1120mm 1650x1200mm Minimum paper size 400x450mm 400x450mm 500x550mm Maximum die cutting size 1280x910mm 1500x1100mm 1630x1180mm Design speed of machine 5000pcs/h 5000pcs/h 5000pcs/h Economic speed of machine 0-5000pcs/h Die-cutting paper type E,D.B,C,A and AB flute corrugated paper(1-8.5mm thickness) Die-cutting precision ≤±0.5mm Max. working pressure 350T 380T 400T Total power 25KW 26.5KW 32KW Feeding part

● Use high quality steel to install and fix firmly, easy to operate.

● Can be in the normal continuation of paper work, code installed the next die-cutting paper, there is no need to cause code paper link caused by the waste of time.

● The use of the patented preedge feed structure can effectively prevent and reduce the damage to the paper printing surface.

● The leading edge feed adopts vacuum adsorption feed and is driven by domestic famous brand servo motor.

● Equipped with counter photoelectric, can automatically rise and fall, but also according to whether the paper is bent, adjust the photoelectric position, in order to ensure that the feeding front and the paper baffle flat.Feeding Table

● It is equipped with opposite photoelectricity. It can automatically lift and manually adjust the lifting distance.

● It can also adjust the photoelectric position according to whether the paper is bent or not, so as to ensure that the front edge of the continued paper is flush with the feed baffle.Die-cutting part and Delivery system

● The maximum die-cutting pressure

● of the main machine is 350N/cm².

● The main engine is driven by worm wheel and worm, with large torque, stable and reliable transmission, low noise and long service life.

● The main wall panel is made of high quality ductile iron, and the upper platform and the moving platform are also made of high quality ductile iron, so as to ensure its ability to resist compression, deformation and vibration.

● And equipped with a forced lubricating oil pump, the realization of each lubrication point oil quantity. Die - cutting knife version easy installation, extraction freely, short version time.(the bearings and electrical parts are selected from well-known foreign brands)Stacker part

● Automatic counting, scattered board alarm. Automatic drop of paper receiving, automatic warning and falling of paper receiving full.

● According to the size of the product, adjust the left and right and front and back of the paperboard to achieve the paper receiving level.Electric system

● The electronic control system is controlled by PLC and equipped with various safety protection devices. When the fault occurs, the sound and light alarm will be given and the machine will stop automatically to ensure the safety of man and machine.

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

Get Quote Now

Feel free to leave us a message for any inquiry, we will respond within 24 hours.