- 产品描述

-

Product Introduction

Our equipment is suitable for various types of corrugated boxes, all equipment can be customized according to customer needs. We have a professional team to recommend suitable and cost-effective equipment to meet your production needs and save your budget. One model for many needs.

Product Parameter

No. Technology project Five Layers Three Layers 1 Maximum production width 1800 mm 1800mm 2 Design speed 150 m/min 120m/min 3 Economic speed 100-120 m/min 60-100 m/min 4 Commissioning temperature ≥175 ℃ ≥172 ℃ 5 Base paper grades ≥level B ≥level B 6 Base paper moisture content 10%±2% 11%±2% 7 Tissue 100~250g/m2 100~180g/m2 8 The core of paper 100~250g/m2 80~160g/m2 9 Tile paper 100- 200g/m2 90~160g/m2 10 Corrugated type combination A, B, C, E

(customer can customize)A, B, C, E

(customer can customize)11 Maximum steam pressure 16Kg/cm² 16kg/cm² 12 Common steam pressure 10-12Kg/cm² 8-12kg/cm² 13 The total amount of steam 2500-3000KG/h 1000-1500KG/h 14 Compressed air pressure

is commonly used0.8-1.1Mpa(4-8kg/cm² ) 5-7kg/cm² 15 Maximum

compressed air pressure1.2Mpa(9kg/cm² ) 8kg/cm² 16 Overall

compressed air consumptionAbout after 1 m³/min 1 m³/min 17 The power supply 380V, 50HZ,

three-phase four-wire system

(foreign voltage can be customized)380V 50Hz

Three-phase four-wire system

(foreign voltage can be customized)18 Total installed power

of equipmentAbout 220 KW About 120KW 19 Actual electricity

consumptionAbout 150KW(full speed) About 80KW(full speed) 20 Equipment cover area About 70m x 10m x 4.5m

(the specific length is subject

to the foundation drawing)About 45m×8m×4.5m

(The specific length shall be subject

to the foundation diagram)21 Forecast production Output of about

6-70,000 square meters in 8 hours22 Paper outlet direction

of the deviceAccording to the user workshop

to determine the left or right driveAccording to the user workshop

to determine the left or right drive23 Suitability of equipment Available A, B, C

grade domestic base paper

or imported base paperavailable A, B, C

grade domestic base paper

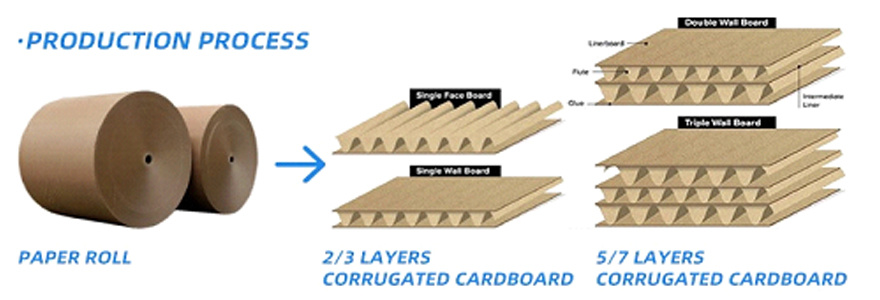

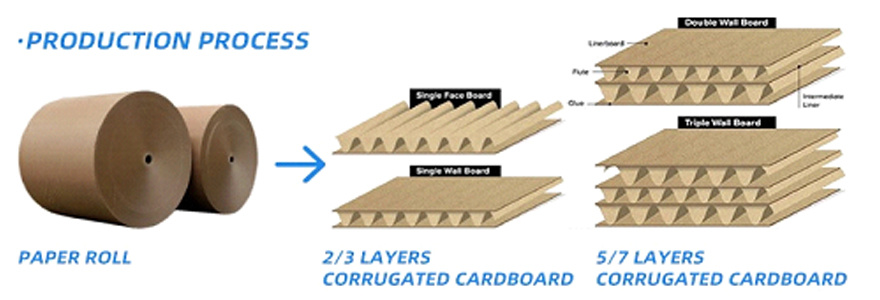

or imported base paper.If there is any other technical correction, no further notice will be given Production Process

Sample Display

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

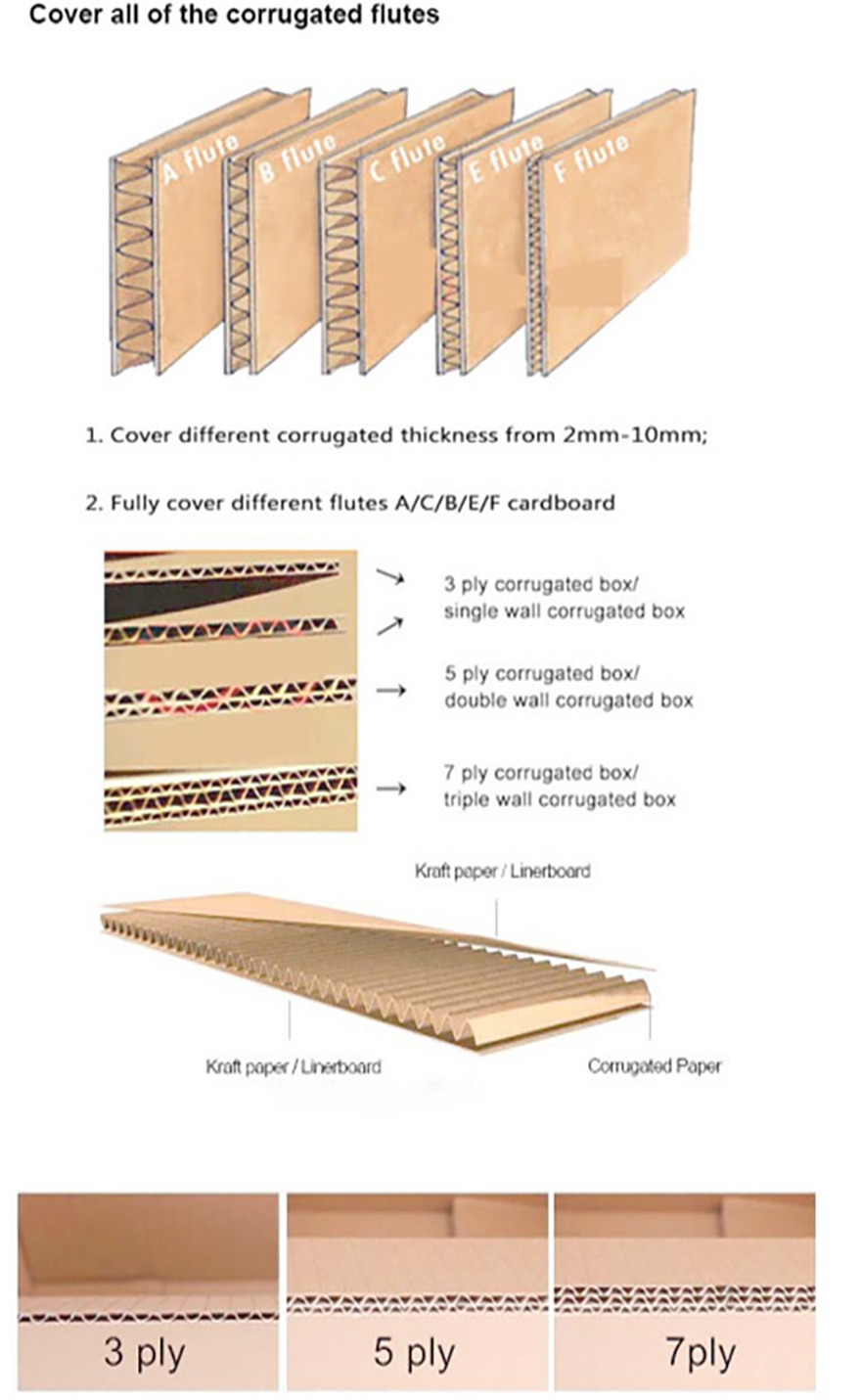

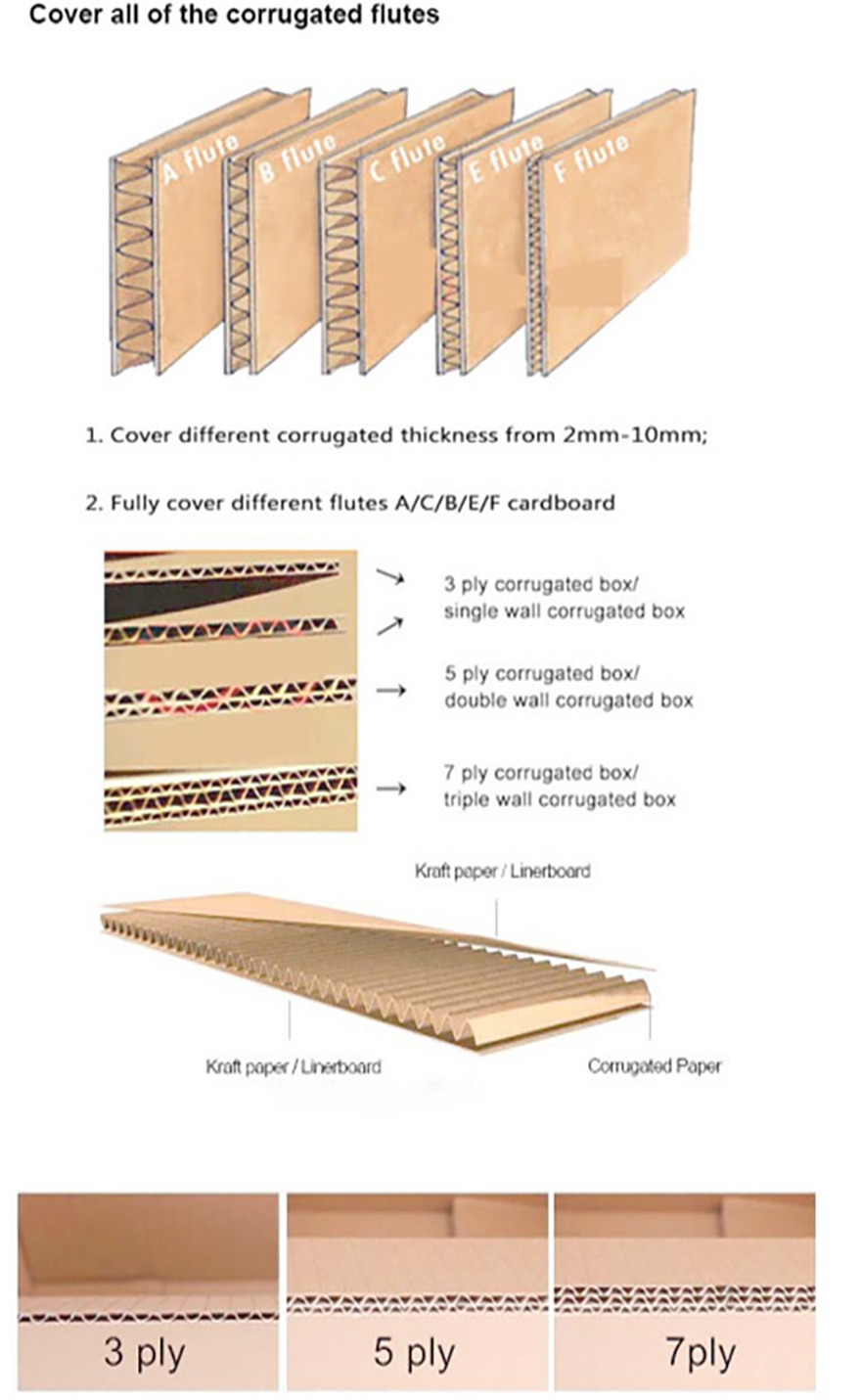

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

Corrugated board production line

Share to

- 产品描述

-

Product Introduction

Our equipment is suitable for various types of corrugated boxes, all equipment can be customized according to customer needs. We have a professional team to recommend suitable and cost-effective equipment to meet your production needs and save your budget. One model for many needs.

Product Parameter

No. Technology project Five Layers Three Layers 1 Maximum production width 1800 mm 1800mm 2 Design speed 150 m/min 120m/min 3 Economic speed 100-120 m/min 60-100 m/min 4 Commissioning temperature ≥175 ℃ ≥172 ℃ 5 Base paper grades ≥level B ≥level B 6 Base paper moisture content 10%±2% 11%±2% 7 Tissue 100~250g/m2 100~180g/m2 8 The core of paper 100~250g/m2 80~160g/m2 9 Tile paper 100- 200g/m2 90~160g/m2 10 Corrugated type combination A, B, C, E

(customer can customize)A, B, C, E

(customer can customize)11 Maximum steam pressure 16Kg/cm² 16kg/cm² 12 Common steam pressure 10-12Kg/cm² 8-12kg/cm² 13 The total amount of steam 2500-3000KG/h 1000-1500KG/h 14 Compressed air pressure

is commonly used0.8-1.1Mpa(4-8kg/cm² ) 5-7kg/cm² 15 Maximum

compressed air pressure1.2Mpa(9kg/cm² ) 8kg/cm² 16 Overall

compressed air consumptionAbout after 1 m³/min 1 m³/min 17 The power supply 380V, 50HZ,

three-phase four-wire system

(foreign voltage can be customized)380V 50Hz

Three-phase four-wire system

(foreign voltage can be customized)18 Total installed power

of equipmentAbout 220 KW About 120KW 19 Actual electricity

consumptionAbout 150KW(full speed) About 80KW(full speed) 20 Equipment cover area About 70m x 10m x 4.5m

(the specific length is subject

to the foundation drawing)About 45m×8m×4.5m

(The specific length shall be subject

to the foundation diagram)21 Forecast production Output of about

6-70,000 square meters in 8 hours22 Paper outlet direction

of the deviceAccording to the user workshop

to determine the left or right driveAccording to the user workshop

to determine the left or right drive23 Suitability of equipment Available A, B, C

grade domestic base paper

or imported base paperavailable A, B, C

grade domestic base paper

or imported base paper.If there is any other technical correction, no further notice will be given Production Process

Sample Display

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

Get Quote Now

Feel free to leave us a message for any inquiry, we will respond within 24 hours.