- 产品描述

-

Performance characteristics

● Computerized high-speed lamination, up to 12,000 sheets per hour (paper length 700mm).

● Stream flow paper feeding head, equipped with 4 sets of "forward suction nozzles" and 2 sets of "up and down suction nozzles".

● Feeder seat: E-shaped low-table cardboard stacking design, the laminated paper can be moved into position with a trailer, and an optional additional rail-assisted pre-stacking stacking table is available.

● Glue coating device: high-precision coating and conveying with paper detaching device to prevent paper from being rolled in and rubber wheel side stop glue mechanism automatic liquid level control: high-speed control to prevent glue overflow and adjust glue backflow.

● Sensing compensation alignment device: It uses multiple sets of inductors to detect the forward and correct position of the bottom line, so that the servo motors on both sides of the tissue paper can perform independent transmission to compensate for the alignment of the upper and lower paper, making it precise and smooth.

● Full-featured electronic control system: using human-machine interface and PLC program light display, it can automatically detect operating conditions, abnormal display and work records, and the electrical design complies with CE standards.

● Paper delivery mechanism: Optional fluff-type paper mechanism can fluff the overlapped and pressed finished products first and then push them together to ensure neat and smooth paper delivery.

Machine Main Parameter

Maximum paper size 1450x1450mm Minimum paper size 400x400mm Paper thickness 180g/m²-1100g/m² Applicable thickness of bottom paper 0.5-10mm Maximum running speed 150m/min Maximum machine speed 12000pcs/min Fitting precision ±1mm Overal dimension(length:including pre-feeding track)(width:including the pedal) 16×2.6×2.4M Weight of machine 10T Total power 20KW SUPPLIER TONGBAO CARTON MACHINERY PRODUCTION STANDARDS EU CE certicification standards MODEL HBZ-1450--1450x1450MM-12000S/H DESCRIPTION HBZ-1450-1450x1450mm High speed fully automatic flute laminator machine FEEDER SECTION

● Equipped with a high-speed automatic dedicated feeder head, the paper lifting nozzle can freely adjust the paper lifting angle, and the paper feeding suction nozzle can adjust the paper feeding angle, regardless of thick paper or thin paper, ensuring high-speed and smooth paper feeding.

PRE-STACK SYSTEM

● The next pile of tissue paper can be pre-stacked without stopping the machine to improve efficiency.

FEEDER

● Paper feeding mechanism, suitable for paper feeding of various large size thick cardboards

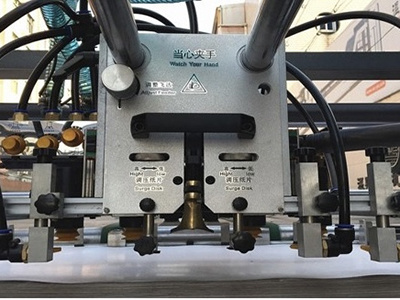

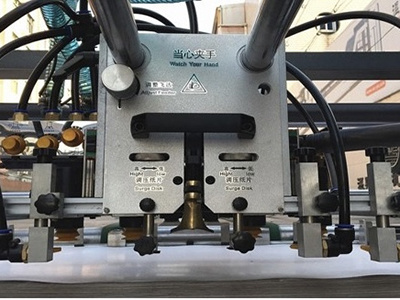

TRANSMISSION SYSTEM

● It adopts imported double-sided toothed synchronous belt transmission and is equipped with a tensioning device to ensure accurate, stable and low-noise transmission.

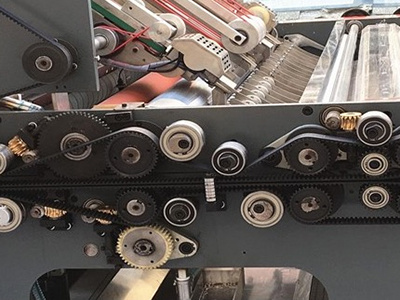

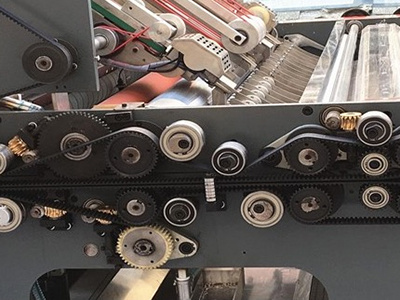

POSITIONING SYSTEM

● Use multiple sets of photoelectric sensors to sense the relative advancing position of the bottom paper, and control the servo motors on both sides of the top paper to perform independent compensation actions to accurately fit the top paper and bottom paper.

GLUING SYSTEM

● Use stainless steel glue roller, which will never rust. After fine grinding, the glue amount is adjusted to the minimum to ensure uniform glue. The lower roller is cleaned with water roller.

ELECTRICAL SYSTEM

● Designed in compliance with European CE standards to ensure the stability, high efficiency and low failure rate of the entire machine. Combining the human-machine interface with PLC, various information such as alarms, detected faults, abnormal conditions and operating speeds are displayed on the screen clearly at a glance.

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

HBZ-High speed fully automatic flute laminator machine

Share to

- 产品描述

-

Performance characteristics

● Computerized high-speed lamination, up to 12,000 sheets per hour (paper length 700mm).

● Stream flow paper feeding head, equipped with 4 sets of "forward suction nozzles" and 2 sets of "up and down suction nozzles".

● Feeder seat: E-shaped low-table cardboard stacking design, the laminated paper can be moved into position with a trailer, and an optional additional rail-assisted pre-stacking stacking table is available.

● Glue coating device: high-precision coating and conveying with paper detaching device to prevent paper from being rolled in and rubber wheel side stop glue mechanism automatic liquid level control: high-speed control to prevent glue overflow and adjust glue backflow.

● Sensing compensation alignment device: It uses multiple sets of inductors to detect the forward and correct position of the bottom line, so that the servo motors on both sides of the tissue paper can perform independent transmission to compensate for the alignment of the upper and lower paper, making it precise and smooth.

● Full-featured electronic control system: using human-machine interface and PLC program light display, it can automatically detect operating conditions, abnormal display and work records, and the electrical design complies with CE standards.

● Paper delivery mechanism: Optional fluff-type paper mechanism can fluff the overlapped and pressed finished products first and then push them together to ensure neat and smooth paper delivery.

Machine Main Parameter

Maximum paper size 1450x1450mm Minimum paper size 400x400mm Paper thickness 180g/m²-1100g/m² Applicable thickness of bottom paper 0.5-10mm Maximum running speed 150m/min Maximum machine speed 12000pcs/min Fitting precision ±1mm Overal dimension(length:including pre-feeding track)(width:including the pedal) 16×2.6×2.4M Weight of machine 10T Total power 20KW SUPPLIER TONGBAO CARTON MACHINERY PRODUCTION STANDARDS EU CE certicification standards MODEL HBZ-1450--1450x1450MM-12000S/H DESCRIPTION HBZ-1450-1450x1450mm High speed fully automatic flute laminator machine FEEDER SECTION

● Equipped with a high-speed automatic dedicated feeder head, the paper lifting nozzle can freely adjust the paper lifting angle, and the paper feeding suction nozzle can adjust the paper feeding angle, regardless of thick paper or thin paper, ensuring high-speed and smooth paper feeding.

PRE-STACK SYSTEM

● The next pile of tissue paper can be pre-stacked without stopping the machine to improve efficiency.

FEEDER

● Paper feeding mechanism, suitable for paper feeding of various large size thick cardboards

TRANSMISSION SYSTEM

● It adopts imported double-sided toothed synchronous belt transmission and is equipped with a tensioning device to ensure accurate, stable and low-noise transmission.

POSITIONING SYSTEM

● Use multiple sets of photoelectric sensors to sense the relative advancing position of the bottom paper, and control the servo motors on both sides of the top paper to perform independent compensation actions to accurately fit the top paper and bottom paper.

GLUING SYSTEM

● Use stainless steel glue roller, which will never rust. After fine grinding, the glue amount is adjusted to the minimum to ensure uniform glue. The lower roller is cleaned with water roller.

ELECTRICAL SYSTEM

● Designed in compliance with European CE standards to ensure the stability, high efficiency and low failure rate of the entire machine. Combining the human-machine interface with PLC, various information such as alarms, detected faults, abnormal conditions and operating speeds are displayed on the screen clearly at a glance.

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

Get Quote Now

Feel free to leave us a message for any inquiry, we will respond within 24 hours.