- 产品描述

-

Features

The high-speed computerized paper cutter is an economical and practical paper cutter. The modified machine is suitable for high-weight paper. It cuts paper without burrs and dust. It successfully solves the problem of dust in subsequent printing and greatly improves work efficiency. The machine adopts high-quality Wei Luntong color touch screen and is controlled by Yonghong PLC. The operation is simple and reliable, and the display is intuitive. High-precision servo drive motor, mechatronics design; neat paper management, front and left and right snap functions, counting and automatic label insertion devices. Computer controlled fully automatic operation, high efficiency, high precision and high degree of automation.

The host machine is driven by Dequchi servo motor. High precision, compact structure, lower inertia, and high dynamic response characteristics. Unique low-speed high torque characteristics and synchronization function. Excellent servo characteristics can be achieved. Save electricity.

Delta variable frequency controller, low speed and large torque, high positioning accuracy, fast response without overshoot.Blade imported from Taiwan, tungsten steel welded edge, raw materials from Taiwan, long blade life (up to one year).

The cutter shaft adopts national standard 45# and is tempered to never deform. Both ends use bearings imported from Japan NSK, which have long life and high precision.

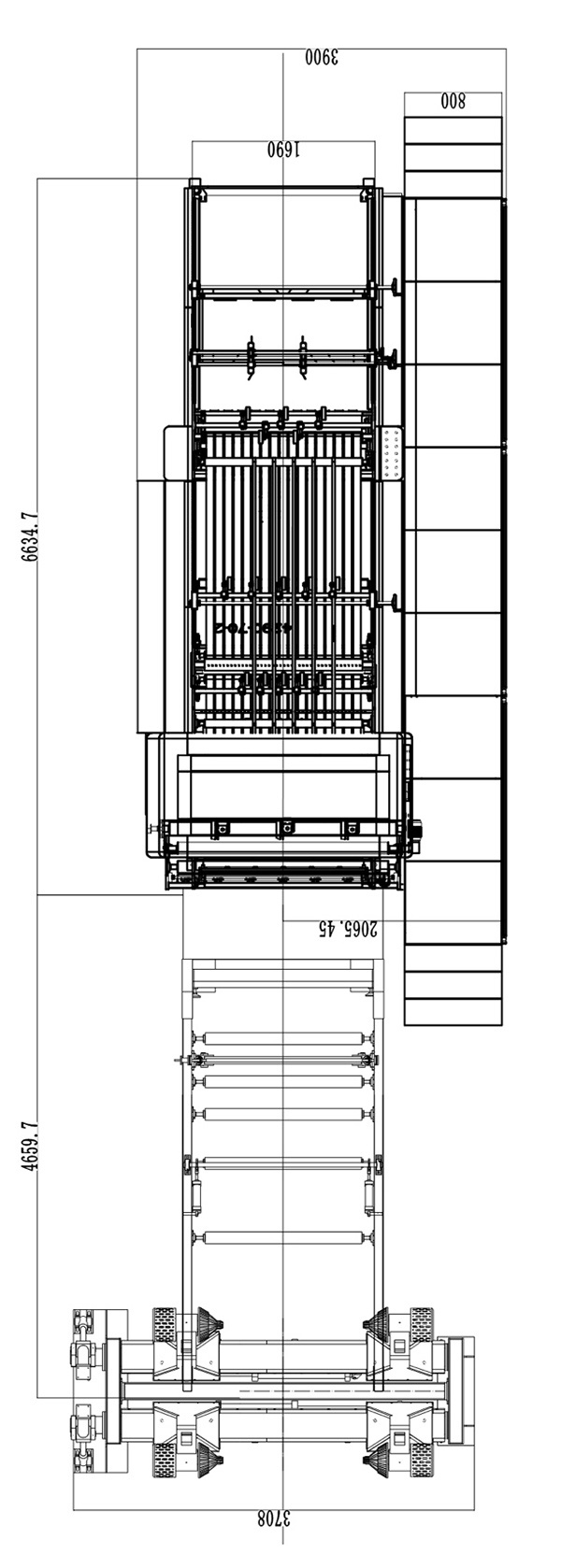

The main technical parameters

Model: 1400 high-speed computer paper cutter

1. Design speed: 350m/min, economical speed: 260m-300m/min

2. The length of the paper cutter (the specific length is subject to the foundation drawing) is about 12 meters

3. Paper cutting accuracy ±0.3mm (at constant speed), less than 1.5 meters

4. Cutting length: 450-1650mm (can be customized according to customer requirements)

5. Cutting paper thickness: 50g-550g/㎡

6. Paper receiving height: 1500mm

7. Machine center height: 1700mm

8. Total motor power: about 25-30KW

9. Warranty time: Within 12 months after commissioning and installation

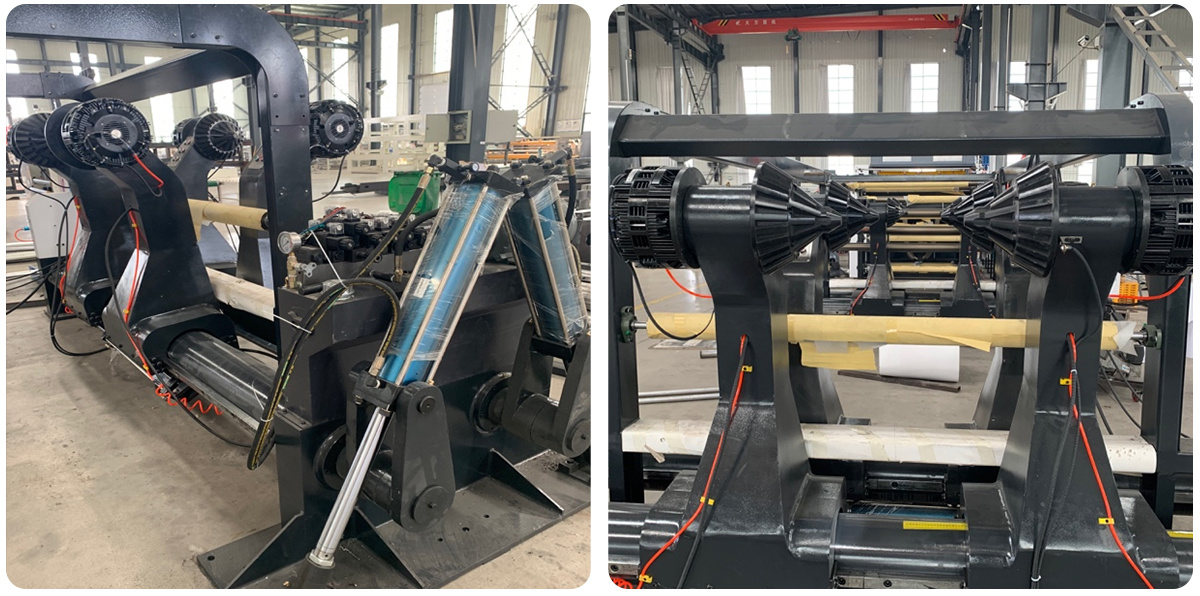

Hydraulic shaftless bracket

Technical Parameters

● Original paper holder action mode: Fully hydraulic action

● Paper clamping range (working width): Maximum 1400mm Minimum 500mm

● Paper diameter: Maximum φ1800mm Minimum φ350mm

● Maximum load on one side: Maximum 2000kg

● Bracket spindle diameter: diameter φ240mm

● Gas source working pressure (MPa): 0.6~0.9MPa

● Total equipment power: 3.75kw

● Working power supply: voltage 380V frequency 50Hz

● Overall dimensions of the machine: 4008×1600×1650 (length×width×height)

Hydraulic system parameters

● Working pressure (MPa): 12~16 MPa

● Hydraulic cylinder working range (swing): φ100mm×460mm

● Hydraulic cylinder diameter (clamping): φ63mm×750mm

● Hydraulic station motor power: 3.7kw Origin: Tianjin Short-time working Voltage 380V

● Hydraulic station solenoid valve working voltage: 220V 50Hz Origin: Tianjin (Shengtian Oil Research)

Structural features

● Tapered cast iron paper clamping head, suitable for 3-12 inch paper rolls.

● Tension control adopts multi-point brakes and automatic tension control, saving labor, time and effort.

● The symmetrical structure can install and cut two original rolls of paper at the same time.

● Using hydraulic drive, it can complete the lifting, clamping, loosening and moving centering of the base paper.

Cutting department

● The front section adopts a lightweight alloy matte roller and a reasonably designed anti-curvature frame to ensure the flatness of the paper.

● High-precision synchronous pulley, with manufacturing accuracy of level 6 or above, low noise and smooth transmission.

● The host adopts Shanghai Dechichi servo drive motor and German Kobe servo drive, which are of high quality, fast response and precise action.

● Paper feeding adopts Shanghai Dexuchi variable frequency motor and Taiwan Yonghong variable frequency drive.

● Tungsten steel blade, tungsten steel welded edge, long blade life (up to one year).

Paper feeding section

● The conveying is divided into two stages: the first stage is high-speed conveying, so that the cut whiteboard paper can quickly detach from the cutter shaft; the second stage is slow-speed conveying, so that the whiteboard paper can be superimposed and run; it can quickly enter the stacking section. Between the first and second conveying sections, an air suction device is installed so that the whiteboard paper can be stacked neatly and stacked into piles.

● The rear section of conveying is equipped with two sets of paper pressing wheels, one of which can be adjusted forward and backward according to the length of the cut paper.

● Maximum cutting length 1500

Stacking Department

● The stacking section is equipped with front paper shooting, side paper shooting and rear baffle devices. The front paper-flapping device is an electromechanical swing device; the side-flapping paper is controlled by a pneumatic vibration valve, making the stacking of whiteboard paper neat and beautiful. The rear baffle device can adjust its position front and back according to the length of the whiteboard paper.

● The stacking part is equipped with a label insertion device, which automatically counts and inserts label paper.

● Maximum stacking height 1500mm

1 Paper cutter Tungsten steel knife Shenzhen 14 Display Wei Luntong Shenzhen 2 Bearing NSK Japan 15 Main knife peripheral bearing FAG7312 Germany 3 Main motor Dequchi Shanghai 16 Paper feed shaft bearing NJ213 Germany 4 Servo controller Kobe Germany 17 Rubber shaft bearing NSK6212 Japan 5 Paper feed motor Dequchi Shanghai 18 Paper feed main drive bearing NSK6210 Japan 6 Frequency converter Delta Taiwan 19 Fast segment bearing NSK6207 Japan 8 PLC Yonghong Taiwan 20 Upper paper frame bearing NSK30310 9 Low voltage electrical appliances Chint China 21 Slow speed section bearing NSK6208,

6205,620610 Electric proportional valve Japan SMC 22 Mounted bearing FK206,

207,20811 Hydraulic system Yuken Tianjin 23 Transmission belt 2352-8m-602000-8m-35

1792-8m-60

1320-8m-301 Pcs

1 Pcs

1 Pcs

1 Pcs12 Timing belt Sheng Lei Jiangsu 24 conveyor belt 4290x70x1.5

1530x70x1.5

5800x25x1.517 Pcs

17 Pcs

5 Pcs13 Pneumatic components Somai Zhejiang 25

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

High speed paper cutter

Share to

- 产品描述

-

Features

The high-speed computerized paper cutter is an economical and practical paper cutter. The modified machine is suitable for high-weight paper. It cuts paper without burrs and dust. It successfully solves the problem of dust in subsequent printing and greatly improves work efficiency. The machine adopts high-quality Wei Luntong color touch screen and is controlled by Yonghong PLC. The operation is simple and reliable, and the display is intuitive. High-precision servo drive motor, mechatronics design; neat paper management, front and left and right snap functions, counting and automatic label insertion devices. Computer controlled fully automatic operation, high efficiency, high precision and high degree of automation.

The host machine is driven by Dequchi servo motor. High precision, compact structure, lower inertia, and high dynamic response characteristics. Unique low-speed high torque characteristics and synchronization function. Excellent servo characteristics can be achieved. Save electricity.

Delta variable frequency controller, low speed and large torque, high positioning accuracy, fast response without overshoot.Blade imported from Taiwan, tungsten steel welded edge, raw materials from Taiwan, long blade life (up to one year).

The cutter shaft adopts national standard 45# and is tempered to never deform. Both ends use bearings imported from Japan NSK, which have long life and high precision.

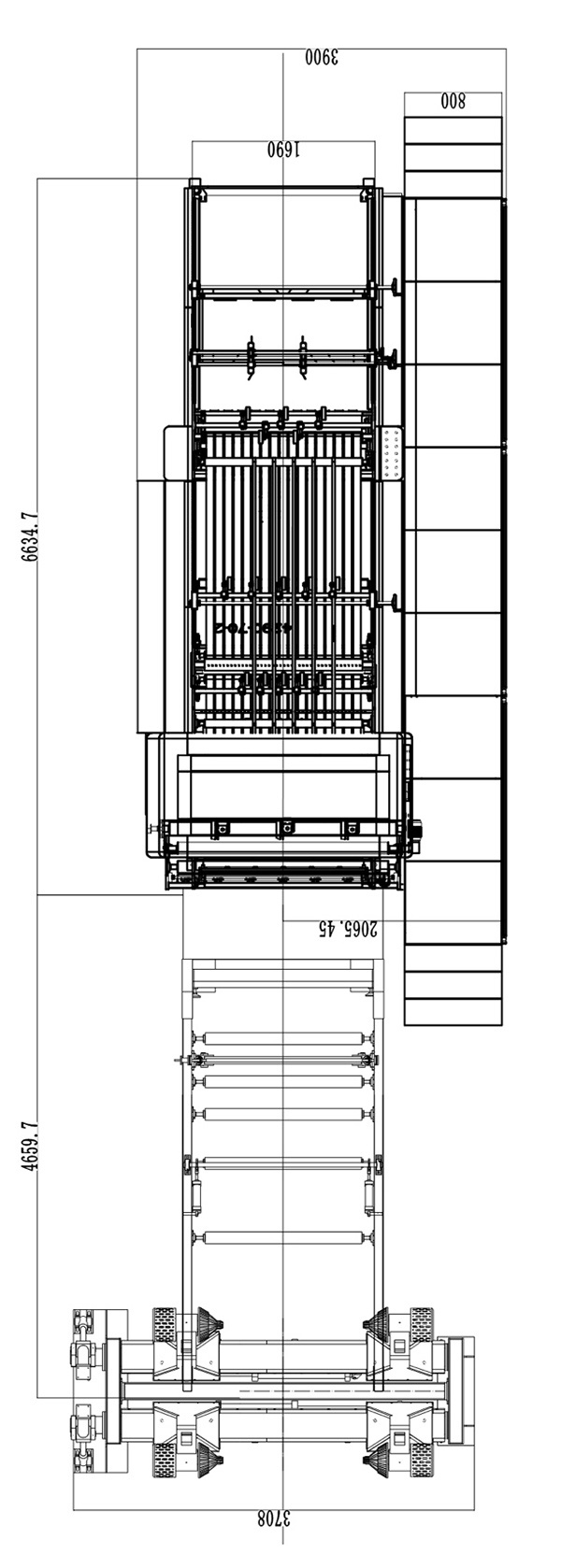

The main technical parameters

Model: 1400 high-speed computer paper cutter

1. Design speed: 350m/min, economical speed: 260m-300m/min

2. The length of the paper cutter (the specific length is subject to the foundation drawing) is about 12 meters

3. Paper cutting accuracy ±0.3mm (at constant speed), less than 1.5 meters

4. Cutting length: 450-1650mm (can be customized according to customer requirements)

5. Cutting paper thickness: 50g-550g/㎡

6. Paper receiving height: 1500mm

7. Machine center height: 1700mm

8. Total motor power: about 25-30KW

9. Warranty time: Within 12 months after commissioning and installation

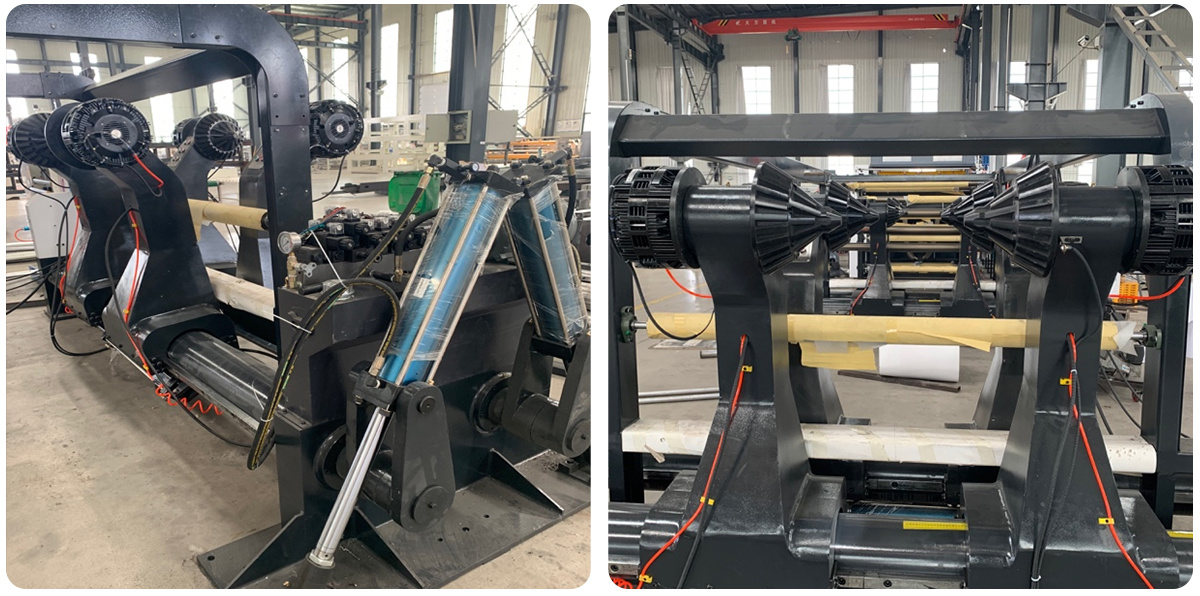

Hydraulic shaftless bracket

Technical Parameters

● Original paper holder action mode: Fully hydraulic action

● Paper clamping range (working width): Maximum 1400mm Minimum 500mm

● Paper diameter: Maximum φ1800mm Minimum φ350mm

● Maximum load on one side: Maximum 2000kg

● Bracket spindle diameter: diameter φ240mm

● Gas source working pressure (MPa): 0.6~0.9MPa

● Total equipment power: 3.75kw

● Working power supply: voltage 380V frequency 50Hz

● Overall dimensions of the machine: 4008×1600×1650 (length×width×height)

Hydraulic system parameters

● Working pressure (MPa): 12~16 MPa

● Hydraulic cylinder working range (swing): φ100mm×460mm

● Hydraulic cylinder diameter (clamping): φ63mm×750mm

● Hydraulic station motor power: 3.7kw Origin: Tianjin Short-time working Voltage 380V

● Hydraulic station solenoid valve working voltage: 220V 50Hz Origin: Tianjin (Shengtian Oil Research)

Structural features

● Tapered cast iron paper clamping head, suitable for 3-12 inch paper rolls.

● Tension control adopts multi-point brakes and automatic tension control, saving labor, time and effort.

● The symmetrical structure can install and cut two original rolls of paper at the same time.

● Using hydraulic drive, it can complete the lifting, clamping, loosening and moving centering of the base paper.

Cutting department

● The front section adopts a lightweight alloy matte roller and a reasonably designed anti-curvature frame to ensure the flatness of the paper.

● High-precision synchronous pulley, with manufacturing accuracy of level 6 or above, low noise and smooth transmission.

● The host adopts Shanghai Dechichi servo drive motor and German Kobe servo drive, which are of high quality, fast response and precise action.

● Paper feeding adopts Shanghai Dexuchi variable frequency motor and Taiwan Yonghong variable frequency drive.

● Tungsten steel blade, tungsten steel welded edge, long blade life (up to one year).

Paper feeding section

● The conveying is divided into two stages: the first stage is high-speed conveying, so that the cut whiteboard paper can quickly detach from the cutter shaft; the second stage is slow-speed conveying, so that the whiteboard paper can be superimposed and run; it can quickly enter the stacking section. Between the first and second conveying sections, an air suction device is installed so that the whiteboard paper can be stacked neatly and stacked into piles.

● The rear section of conveying is equipped with two sets of paper pressing wheels, one of which can be adjusted forward and backward according to the length of the cut paper.

● Maximum cutting length 1500

Stacking Department

● The stacking section is equipped with front paper shooting, side paper shooting and rear baffle devices. The front paper-flapping device is an electromechanical swing device; the side-flapping paper is controlled by a pneumatic vibration valve, making the stacking of whiteboard paper neat and beautiful. The rear baffle device can adjust its position front and back according to the length of the whiteboard paper.

● The stacking part is equipped with a label insertion device, which automatically counts and inserts label paper.

● Maximum stacking height 1500mm

1 Paper cutter Tungsten steel knife Shenzhen 14 Display Wei Luntong Shenzhen 2 Bearing NSK Japan 15 Main knife peripheral bearing FAG7312 Germany 3 Main motor Dequchi Shanghai 16 Paper feed shaft bearing NJ213 Germany 4 Servo controller Kobe Germany 17 Rubber shaft bearing NSK6212 Japan 5 Paper feed motor Dequchi Shanghai 18 Paper feed main drive bearing NSK6210 Japan 6 Frequency converter Delta Taiwan 19 Fast segment bearing NSK6207 Japan 8 PLC Yonghong Taiwan 20 Upper paper frame bearing NSK30310 9 Low voltage electrical appliances Chint China 21 Slow speed section bearing NSK6208,

6205,620610 Electric proportional valve Japan SMC 22 Mounted bearing FK206,

207,20811 Hydraulic system Yuken Tianjin 23 Transmission belt 2352-8m-602000-8m-35

1792-8m-60

1320-8m-301 Pcs

1 Pcs

1 Pcs

1 Pcs12 Timing belt Sheng Lei Jiangsu 24 conveyor belt 4290x70x1.5

1530x70x1.5

5800x25x1.517 Pcs

17 Pcs

5 Pcs13 Pneumatic components Somai Zhejiang 25

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

Get Quote Now

Feel free to leave us a message for any inquiry, we will respond within 24 hours.