- 产品描述

-

Product Introduction

It integrates the functions of cardboard leading edge feeder, slotting and scoring, longitudinal line pressing, longitudinal slitting, transverse cutting, glue spraying, and hand hole punching into one, making it a multifunctional and highly automated plate less cardboard box machine.

Advantage

● 1-3seconds, quickly complete order change,Each longitudinal and longitudinal cutting is equipped with servo motors, 8 servo motors,more efficient, more accurate,can achieve high and low pressure line

● Easy-style operation, automatic adjustment by computer

● 2.8meters effective paper width, unlimited cardboard length

● The front edge automatically feeds the paper, and one person can complete the machine operation

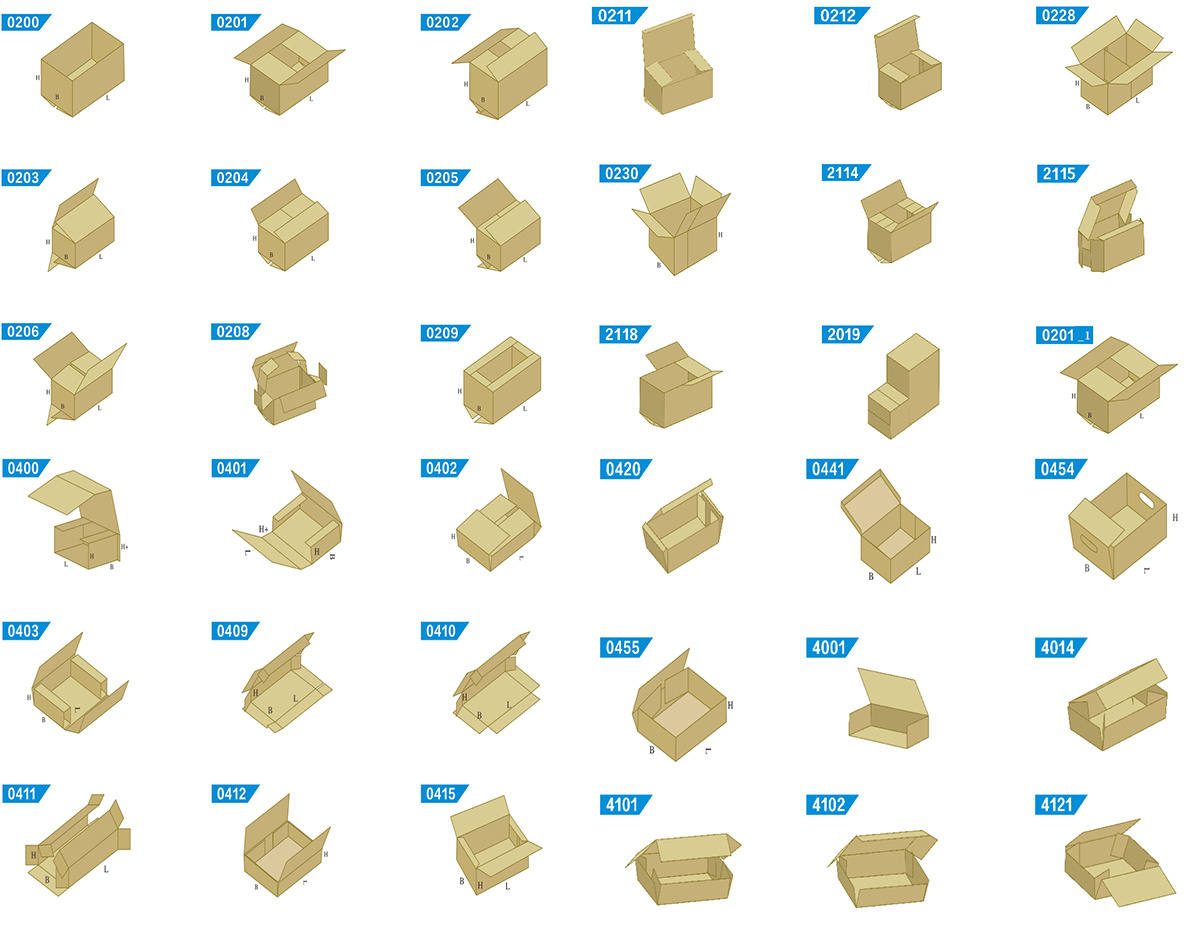

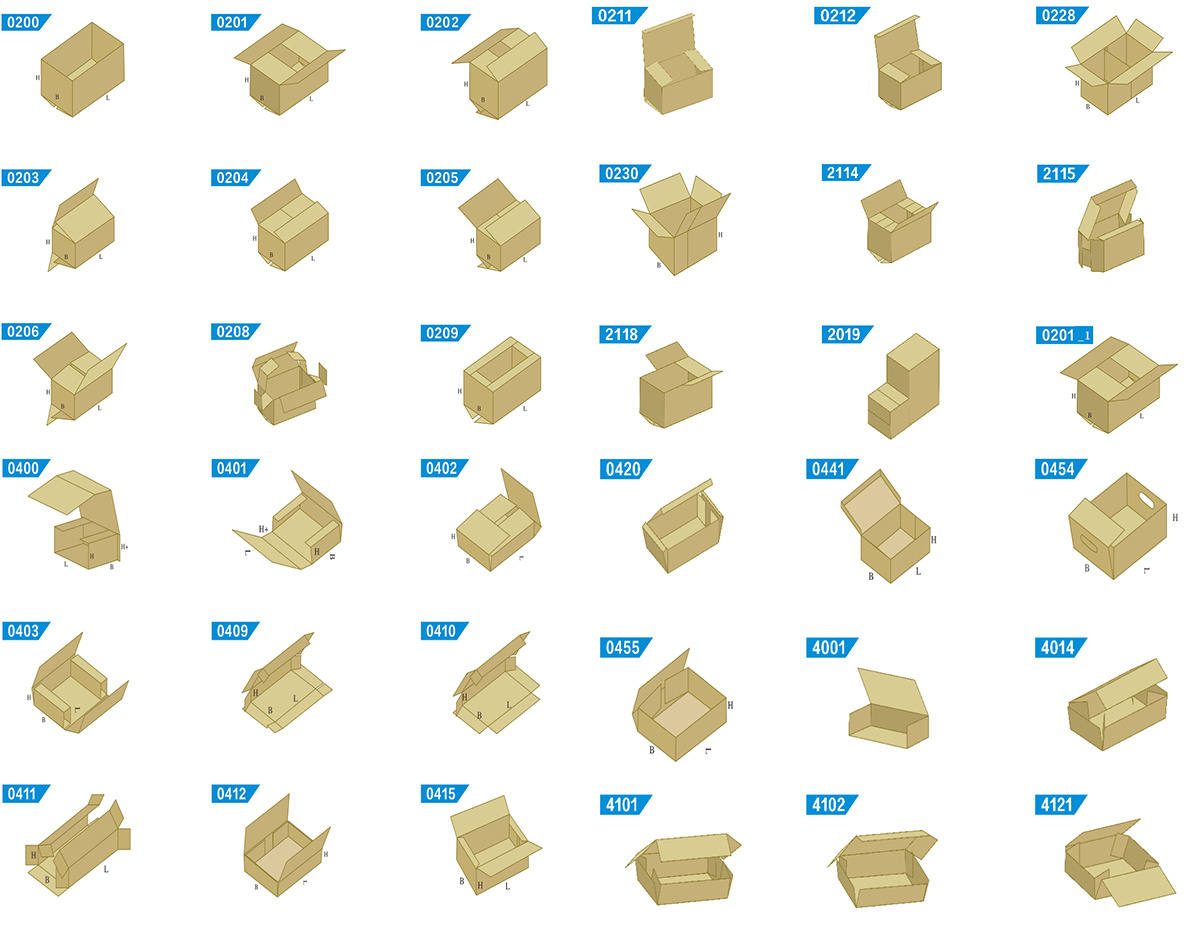

● Nearly 100 kinds of box types are available, no need for plate making, saving time and effort

● Unlimited slotting, any size, any box shape, ready in seconds

● Slotting,slitting, pressing, punching, gluing, and cross cutting are completed in one go, no need for multiple processes

● Automatic adjustment of paperboard and pressure

● External transmission, easier to adjust and maintain

● Eccentric adjustment of line depth, long service life

● The slotting knife is controlled by two servo motors, and the slotting is adjusted in the center

● The helical rack has high precision and long life

● The transmission gear is more durable than the belt, and it is not easy to fail, and there is no need to replace the transmission belt

● Paper press sun wheel pneumatic unified adjustment, paper pressure arbitrary adjustment

● The punching paper part is equipped with pressure wheel, which makes the punching more accurate.Main Function

Automatic paper feed

7.5KW high power leading edge feed paper, precise no skid, no tail.

Automatic slot touch wire

2×500mm Slotting knife, automatic adjustment, cardboard slotting touch line once completed, high efficiency.

Servo drive scuttling

Four servo-driven scutters, made of tungsten steel, imported from Taiwan, carton edges neat and beautiful

Longitudinal compression

Four press wheel, pressure pneumatic adjustment, complex box molding

Horizontal cutting

An active rotating transverse slitting knife removes excess cardboard without the need for an additional paper cutter.

Handle hole

The drilling module with quick disassembly design, hand-held holes, and ventilation holes are processed in one go.

Box Type Warehouse

Boxes can be booked in advance or added remotely.

Machine function, parameters, configuration

Function Predetermined Box Types Support Automatic Feeding Support Slotting Support Scoring Support Creasing Support Slitting Support Transverse Cutting Support Handheld Hole Support Glue Spraying Support (Optional) Remote Maintenance Support Scan Code Support Parameter Table Applicable Cardboard 2-10mm Corrugated Board Use Cardboard Grammage ≤1200g/m² Max Paper Feed Size Unlimited Length, Width 2800mm Mini Paper Feed Size Length 650mm, Width 200mm Minimum slitting and crimping 85mm Change Order Time 3 Seconds Processing Speed 5-10 PCS/Min Standard Slotting Knife 2×500mm(Optional) Slitting Blade No. 4 Crimping Blade No. 4 Cut-off Blade No. 1 Power 22KW ( 380V±10%,50HZ ) Air Source 0.6-0.7MPa, Air Consumption 75L/min Overall Size 3500(W) *1800 ( L) * 2030mm(H) Total Weight About 3500kg Paper Feed Module 3-Axis Leading Edge Feed Punching tool holder 2 Parts Name Brand Producer Linear Rail Airtac Taiwan, China Ball Screw TBI Taiwan, China Bearing HRB Harbin HTD Synchronous Belt Subak Japan Silent Drag Chain CPS Korea Electrical Switch Schneider France Sensor Autonics Korea Switch Power Supply Mean Well China Air Cylinder Airtac Taiwan, China Solenoid Valve Airtac Taiwan, China Servo Motor INVT China PLC Schneider France Touch Screen MCGS China

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

Automatic Box Maker

Share to

- 产品描述

-

Product Introduction

It integrates the functions of cardboard leading edge feeder, slotting and scoring, longitudinal line pressing, longitudinal slitting, transverse cutting, glue spraying, and hand hole punching into one, making it a multifunctional and highly automated plate less cardboard box machine.

Advantage

● 1-3seconds, quickly complete order change,Each longitudinal and longitudinal cutting is equipped with servo motors, 8 servo motors,more efficient, more accurate,can achieve high and low pressure line

● Easy-style operation, automatic adjustment by computer

● 2.8meters effective paper width, unlimited cardboard length

● The front edge automatically feeds the paper, and one person can complete the machine operation

● Nearly 100 kinds of box types are available, no need for plate making, saving time and effort

● Unlimited slotting, any size, any box shape, ready in seconds

● Slotting,slitting, pressing, punching, gluing, and cross cutting are completed in one go, no need for multiple processes

● Automatic adjustment of paperboard and pressure

● External transmission, easier to adjust and maintain

● Eccentric adjustment of line depth, long service life

● The slotting knife is controlled by two servo motors, and the slotting is adjusted in the center

● The helical rack has high precision and long life

● The transmission gear is more durable than the belt, and it is not easy to fail, and there is no need to replace the transmission belt

● Paper press sun wheel pneumatic unified adjustment, paper pressure arbitrary adjustment

● The punching paper part is equipped with pressure wheel, which makes the punching more accurate.Main Function

Automatic paper feed

7.5KW high power leading edge feed paper, precise no skid, no tail.

Automatic slot touch wire

2×500mm Slotting knife, automatic adjustment, cardboard slotting touch line once completed, high efficiency.

Servo drive scuttling

Four servo-driven scutters, made of tungsten steel, imported from Taiwan, carton edges neat and beautiful

Longitudinal compression

Four press wheel, pressure pneumatic adjustment, complex box molding

Horizontal cutting

An active rotating transverse slitting knife removes excess cardboard without the need for an additional paper cutter.

Handle hole

The drilling module with quick disassembly design, hand-held holes, and ventilation holes are processed in one go.

Box Type Warehouse

Boxes can be booked in advance or added remotely.

Machine function, parameters, configuration

Function Predetermined Box Types Support Automatic Feeding Support Slotting Support Scoring Support Creasing Support Slitting Support Transverse Cutting Support Handheld Hole Support Glue Spraying Support (Optional) Remote Maintenance Support Scan Code Support Parameter Table Applicable Cardboard 2-10mm Corrugated Board Use Cardboard Grammage ≤1200g/m² Max Paper Feed Size Unlimited Length, Width 2800mm Mini Paper Feed Size Length 650mm, Width 200mm Minimum slitting and crimping 85mm Change Order Time 3 Seconds Processing Speed 5-10 PCS/Min Standard Slotting Knife 2×500mm(Optional) Slitting Blade No. 4 Crimping Blade No. 4 Cut-off Blade No. 1 Power 22KW ( 380V±10%,50HZ ) Air Source 0.6-0.7MPa, Air Consumption 75L/min Overall Size 3500(W) *1800 ( L) * 2030mm(H) Total Weight About 3500kg Paper Feed Module 3-Axis Leading Edge Feed Punching tool holder 2 Parts Name Brand Producer Linear Rail Airtac Taiwan, China Ball Screw TBI Taiwan, China Bearing HRB Harbin HTD Synchronous Belt Subak Japan Silent Drag Chain CPS Korea Electrical Switch Schneider France Sensor Autonics Korea Switch Power Supply Mean Well China Air Cylinder Airtac Taiwan, China Solenoid Valve Airtac Taiwan, China Servo Motor INVT China PLC Schneider France Touch Screen MCGS China

Factory

Cangzhou Tongbao Carton Machinery Co., Ltd. is a large private enterprise in Cangzhou City specializing in the research and development and production of carton machinery. It has a registered capital of US$500, a plant area of 18,000 square meters, 126 industrial workers and 30 professional technical R&D personnel.

The product structure of the enterprise includes the production and manufacture of all types of carton packaging and printing equipment. Among them, special models such as vacuum adsorption high-speed high-definition automatic water-based printing slotting die-cutting glue box packaging production line, automatic high-speed four-color printing die-cutting machine, automatic flat die-cutting and creasing machine occupy a large share.v

Company Eexhibition

Qualification Certificate

FAQs

★ Whether to support customized services?

Yes, OEM service accepted and supported. Some customers have special requirements for carton machines, such as processing oversized cartons, high-speed high-definition printing, etc. We can customize carton machines according to the specific requirements of customers.

★ How can we visit your factory?

The company has a superior geographical location, located on the east side of National Highway 105 in the south of the county seat, close to the Beijing-Shanghai Railway and the Beijing-Hangzhou Grand Canal, and the Beijing-Shanghai Expressway and railway to the east, with convenient transportation.

★ What is the features of automatic carton gluing machine?

1. Adequate protective measures can avoid the danger of operation.

2. There is sufficient and smooth space for personnel to move from the cardboard to the front of the paper bed.

3. It is convenient to set and adjust the size, including the setting of baffle, folding arm, cardboard, and counting discharge quantity.

★ The difference between single corrugated box and double corrugated box?

1. Different structure: It is not difficult to see from the above definition that single corrugated cardboard box is mainly composed of single corrugated cardboard, and double corrugated cardboard box is mainly composed of double corrugated cardboard;

2. Different characteristics: The edge compression strength and rupture strength of double corrugated boxes are higher than that of single corrugated boxes.

3. The scope of application is different: double corrugated boxes are mainly used for single-piece packaging with lighter weight and easily broken contents. Single corrugated boxes are mainly used to hold small items.

★ How long is the delivery time?

lf the customer needs some machines with standard configuration, we can guarantee that the machines will be completed and delivered within 7 days.

lf the customer needs some customized machines, we can guarantee that the machines will be completed and delivered in about 30 days.

Get Quote Now

Feel free to leave us a message for any inquiry, we will respond within 24 hours.